Building a boat is a multi-step process that requires careful attention to detail, craftsmanship and the right materials. Deciding on the application, durability and beauty of the boat, wood materials will now be the primary consideration for wood-workers. In this article, let’s join K-Timber to learn in detail the 6 best types of wood used to build boat. By understanding the nature and analyzing the potential, you can find the key choice for your boatbuilding projects.

Table of Contents

Iroko

Iroko, commonly known as “African Teak“, is a hardwood native to the western part of tropical Africa, prized for its durability and resistance to rot and decay. Iroko has many of the same physical properties as Teak wood but has a better price. Its natural oils make it highly resistant to marine borers and other pests, making it a top choice for subsea applications.

Iroko is a dense, medium-textured hardwood with grain that creates a beautiful and distinctive appearance. The color of the wood ranges from yellow to medium brown, gradually darkening over time. Its density and interwoven grains contribute to excellent wear and abrasion resistance.

Ideal Uses

Iroko is perfect for decking, hull structures and interiors. The wood’s natural oils and hardness make it perfect for boat decking. It can withstand heavy loads and long periods of exposure to salt water. Its durability and resistance to rot make it suitable for hull planking, ensuring longevity in marine environments. The attractive color and grain of the wood adds elegance to the boat’s interior.

Acajou

Acajou, also known as African Mahogany, is native to Central and West Africa. This type of wood is highly appreciated for its durability, stability and beautiful reddish brown color. During the manufacturing process, Acajou wood has excellent machining and finishing capabilities, making it a popular choice for both structural and decorative elements in boatbuilding.

Acajou has straight to interwoven grain with a medium to coarse texture. The heartwood ranges in color from light pink to reddish brown, gradually darkening with age. This is a medium thickness wood that offers a good balance between weight and strength.

Ideal Uses

Ideal applications for Acajou include hull panels, interior joinery and trim. Acajou’s strength and stability make it ideal for hull construction, providing a durable and aesthetically pleasing finish. Because of its ease of processing and beautiful finish, Acajou is often used by carpenters to make interior panels, cabinets and other woodwork. Acajou’s rich color and fine grain are ideal for decorative elements, adding elegance to the interior and exterior of the boat.

Mukulungu

Mukulungu, native to Central Africa, is known for its density and hardness, making it an excellent choice for structural parts of boats. Mukulungu’s natural resistance to decay and termites makes it suitable for marine environments. Mukulungu is especially prized for its impressive durability and strength, it is one of the few woods that is truly suitable for marine environments because the longer it stays in water, the harder it becomes.

Mukulungu is a dense, heavy wood with a fine to medium texture and straight to interwoven grain. The heartwood has a color ranging from reddish brown to purple brown, and when exposed to light it will darken.

Ideal Uses

Ideal uses for Mukulungu include ship keels, frames and ribs. Mukulungu’s density and strength make it ideal for keel use, providing a solid foundation for the boat. The durability of the wood ensures frames made from Mukulungu can withstand the pressures of the marine environment. Mukulungu’s hardness and resistance to decay make it suitable for ribs, ensuring the structural integrity of the boat.

Cedar

Cedar, especially Western Red Cedar, is highly valued because it’s lightweight and naturally resistant to rot and insects. This wood, native to North America, is popular for its pleasant aroma that helps keep pests away. Plus, it’s easy to work with, making it a great choice for various parts of boats.

Cedar has a straight grain and a uniform texture, along with a distinctive, pleasant smell. The color of the wood ranges from pale yellow to deep reddish-brown. It’s a lightweight material that offers good thermal insulation and sound-damping properties.

Ideal Uses

Cedar is perfect for planking, decking, and building canoes and kayaks. Its lightweight nature and resistance to rot make it ideal for hull planking, helping boats stay buoyant and durable. The natural beauty and resilience of cedar make it great for decking, offering a comfortable and attractive surface. Because of its buoyancy and ease of work, cedar is also a popular choice for smaller boats like canoes and kayaks.

Douglas Fir

Douglas Fir is well-known for its excellent strength-to-weight ratio and resistance to decay when treated. This North American native is widely used in boat-building because it’s readily available and affordable. It’s a versatile wood, suitable for both structural and non-structural applications.

Douglas Fir has a straight grain and a medium to coarse texture. Its color varies from light yellow to reddish-brown. It’s a strong, medium-weight wood that strikes a good balance between strength and workability.

Ideal Uses

Douglas Fir is ideal for masts, spars, and structural components. Its strength and flexibility make it perfect for masts, providing the necessary support for sails. The excellent strength-to-weight ratio ensures that spars made from Douglas Fir can handle the stresses of sailing. Additionally, Douglas Fir’s durability makes it suitable for various structural parts, including frames and ribs.

Marine Plywood

Marine plywood is specially engineered for marine applications. Made with waterproof adhesive and high-quality veneers, it can withstand constant exposure to water without delaminating or warping. This wood product is designed to offer structural integrity and durability in harsh marine environments.

Marine plywood consists of multiple layers of hardwood veneers bonded with waterproof adhesive. It has a smooth, uniform surface and an excellent strength-to-weight ratio. The layers are designed to resist water penetration, ensuring consistent performance.

Ideal Uses

Marine plywood is perfect for hull construction, decks, and cabinets. Its durability and water resistance make it ideal for hull planking, ensuring a long-lasting and stable boat structure. The smooth surface and resistance to water make it great for decking, providing a comfortable and durable walking surface. Marine plywood’s uniformity and ease of work make it perfect for interior cabinetry and joinery, offering both strength and aesthetic appeal.

Conclusion

Selecting the right wood for your boat-building project is key to ensuring your vessel’s durability and performance. Teak, mahogany, white oak, cedar, marine plywood, and Douglas fir each bring unique advantages to different aspects of boat construction. Consider your specific needs, budget, and the type of boat you’re building to make the best choice. Happy building!

Buy Quality, Affordable Iroko Wood at K-TIMBER

Are you looking for a reputable supplier of Iroko wood, offering quality at a reasonable price? K-TIMBER is the perfect choice for you. With over 20 years of experience in the timber export industry and successful exports to over 30 countries worldwide, we have established ourselves as a leading provider of quality Iroko wood.

Should you buy Iroko wood at K-TIMBER?

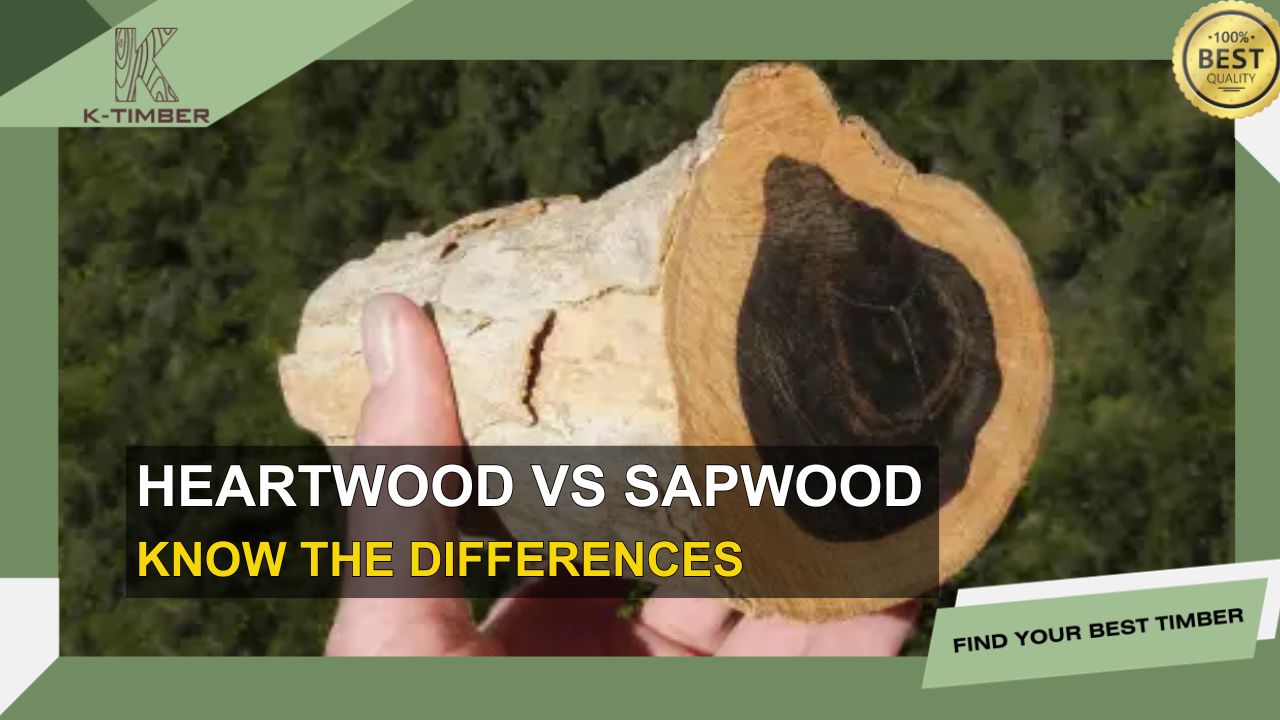

- Top-Quality Wood: K-TIMBER is committed to providing Iroko wood, and other African hardwoods, to the FAS (First and Seconds) grade standard, ensuring up to a 90% yield of high-quality, defect-free wood—free from warping, cracking, heartwood issues, sapwood, and pests, thus guaranteeing a durable and high-quality wood supply for our customers.

- Sustainable Origin: Building a close relationship with the Angolan government, K-TIMBER guarantees a supply of quality wood, sustainably sourced from tropical forests and fully certified by the FSC (Forest Stewardship Council).

- Competitive Pricing: Along with quality, K-TIMBER is confident in offering our customers Iroko wood at prices 20% lower than the market rate. We supply up to 20,000 cubic meters of wood each month.

- Customer Service: The quality of our customer service is also a key factor in the success of K-TIMBER. Our team is always ready to assist and answer any questions from customers 24/7, despite the different time zones in each country.