In recent years, sustainable forestry has become a vital aspect of global environmental policies, and Angola is no exception. K-Timber, a leading timber company in Angola, is at the forefront of implementing sustainable and legal timber harvest practices. This blog will show K–Timber legal timber harvest process in Angola, highlighting the steps this company takes to ensure compliance with environmental regulations and sustainable forestry practices.

Table of Contents

K-Timber legal timber harvest process

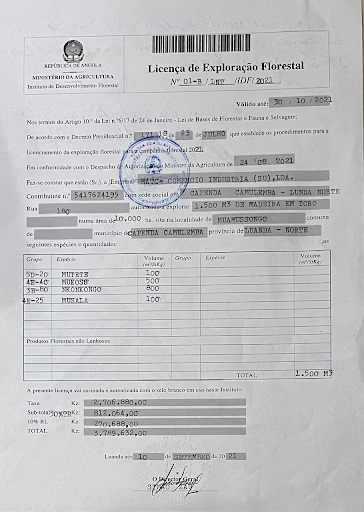

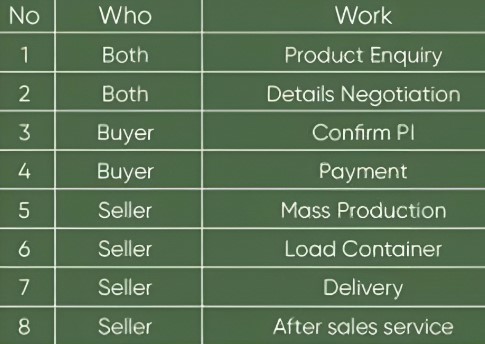

Step 1: To be allowed to exploit timber, HATC needs a timber exploitation permit from the commune by carrying out procedures and taxes at the District. Then, the application will be sent to the province and reviewed to see if the enterprise has the capacity to manage and exploit forests.

Step 2: After the application is approved, HATC proceeds to build facilities and carry out social benefits such as building roads and schools => The locality will license forest management in that area.

Step 3: The provincial level will transfer the application to the central level. Then the central level comes down to check again. If this inspection is passed, all documents will be transferred to the Ministry of Agriculture. Qualified businesses will be issued certificates and forest exploitation licenses including information on wood type, quantity and quality. The dossier set will include the type of wood and legal requirements for exploitation.

Step 4: After receiving the mining license. HATC is allowed to harvest timber.

Step 5: The forest management agency will come to inspect again and issue a permit to transport wood and paper Certificado Origem (CO)

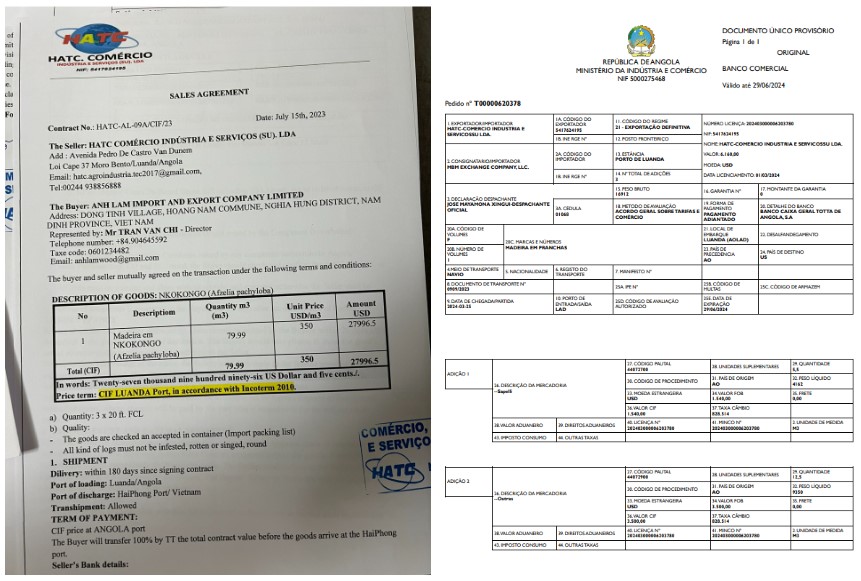

Step 6: After having the full set of above documents including CO, Phyto, B/L, Invoice, CITES. The Ministry of Commerce will send documents to customers to certify that the product is eligible for export.

Step 7: In order for wood to be allowed to be transported, HATC needs to complete 13 types of documents including:

- Direitos Aduameiro (DAR): Customs duty receipt

- Porto De Luanda (EP14): Service fees at Luanda port

- Terminal De Luanda (EP17):

- Trasporte Contentor Vazio: Empty container delivery note

- Trasporte Contentor Cheio: Delivery note for filled container (wood)

- Grua Vazio

- Drua Cheio

- Intervencao Dossier (AGT): Import records of Angolan tax authorities

- Pagament Gasosa (AGT IDP PF)

- Pagamento Santibraga

- Honorários (Nossos Serviços)

- Inerentes

- Licenciamento da Fatura

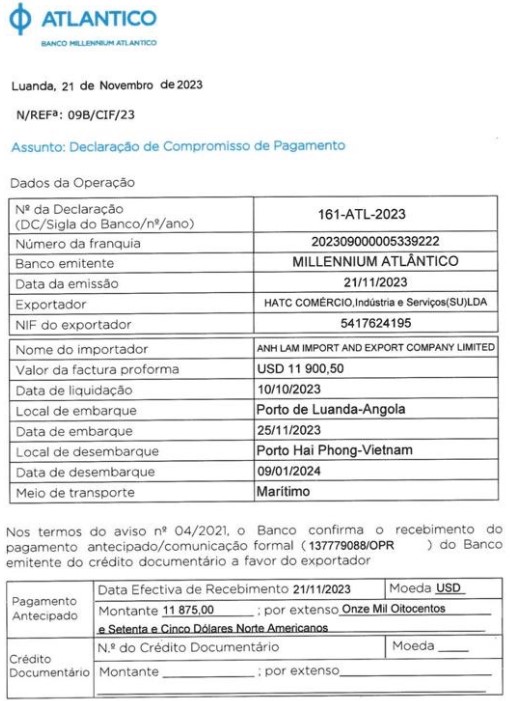

Step 8: The customer sends a receipt with a 30% deposit, and at the same time, HATC goes to the international bank to check the invoice and send the Invoice back to the customer.

Step 9: The General Department of Taxation will require the Angolan bank to prove that the import customer has made a minimum deposit of 30%.

Process 10: Once the payment confirmation is received, HATC will submit it to the Angola General Department of Taxation (AGT) and proceed to use machinery and equipment to load the wood into the Container.

Note: When sending the bill back to the customer, HATC will send a draft bill to the customer first to confirm the final accurate information. Because if the information is not accurate, it will take a lot of time and will also cost more when loading wood into the container.

Before carrying out wood export procedures, you need to ask customers if they need any other documents to have preparation options. Because each country when wood is imported will need other necessary documents as required by that country’s government.

Whether customers pay CIF or FOB, HATC still needs all the above documents and procedures. At the same time, perform the above processes until the wood is loaded into the container.

Sales Procedure Time

- Order Placement to Production Factory: ~15 days (depending on time and weather)

- Phyto Certificate: 15-30 days

- License from the Ministry of Commerce and Bank Certification: ~7 days

- Wood Production and Container Loading: 30-45 days

K-Timber’s commitment to legal and sustainable logging in Angola demonstrates its dedication to environmental stewardship and responsible business practices. By following a strict regulatory framework and applying best practices, K-Timber ensures that its operations benefit both the environment and local communities.

![[K-Timber] Blog Post Boder-3](https://k-timbers.com/wp-content/uploads/2024/06/K-Timber-Blog-Post-Boder-3.png)