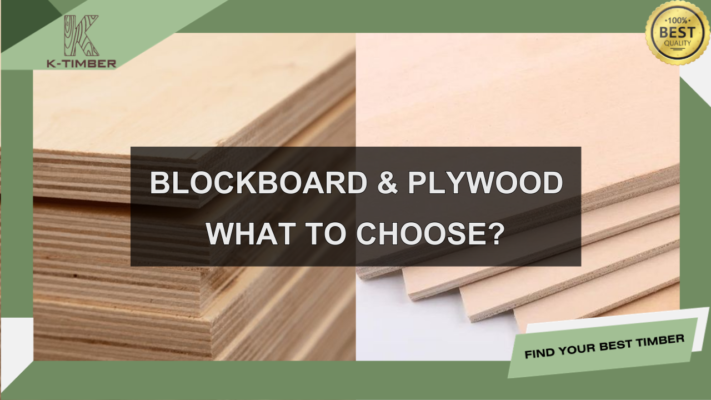

When deciding between blockboard and plywood for construction or furniture projects, it’s essential to understand the differences between these two engineered wood products. Both materials are popular for their durability, versatility, and cost-effectiveness, but they have unique characteristics that make them suitable for different applications. This article will guide you through the key properties of blockboard and plywood, helping you make an informed choice.

Table of Contents

What is Blockboard?

Blockboard is an engineered wood product made from softwood strips that are glued together edge-to-edge and sandwiched between two layers of veneer or plywood. This structure gives blockboard its lightweight properties while maintaining good strength. The softwood core makes it ideal for large furniture pieces or interior partitions, offering stability without being too heavy.

What is Plywood?

Plywood is a layered wood product created by gluing together thin sheets of wood veneer, with each layer’s grain direction perpendicular to the next. This cross-laminated structure gives plywood enhanced strength and durability, making it a popular choice for various construction and furniture projects

Properties of Blockboard and Plywood

Physical Properties

Blockboard is lighter because of its softwood core, making it less dense than plywood. This lower density makes blockboard easier to handle and cut, especially when working with large furniture pieces. In contrast, plywood has a more uniform and denser structure as it is made entirely from wood veneers, which increases its overall strength and allows it to support heavier loads.

Sizes

- Blockboard: Typically available in standard sizes of 8×4 feet, with thicknesses ranging from 12mm to 40mm.

- Plywood: Available in a variety of sizes and thicknesses, usually between 3mm and 25mm. Standard sizes are also around 8×4 feet, but thinner plywood sheets can be more versatile for various applications.

Strength and Durability

While blockboard is strong, it is slightly less durable than plywood when it comes to load-bearing capacity and is more susceptible to warping in areas with high moisture. Plywood, on the other hand, is known for its superior strength and durability, making it ideal for structural applications. Its cross-laminated layers provide enhanced resistance to warping, bending, and cracking, which makes it well-suited for heavy-duty projects.

Manufacturing Process

Blockboard is made by gluing softwood strips edge-to-edge, with veneers attached to both sides, resulting in a simpler and quicker manufacturing process compared to plywood. Plywood, on the other hand, is produced by bonding multiple thin wood veneers together under heat and pressure, with alternating grain directions to enhance strength, making it a more time-intensive product to manufacture.

Uses of Blockboard vs Plywood

Blockboard: Best used for interior applications such as furniture, shelves, cabinets, and doors. Due to its lightweight nature, blockboard is great for making large pieces like wardrobes or room dividers, which don’t require high load-bearing strength.

Plywood: Ideal for both interior and exterior use, plywood is more versatile. It’s commonly used in wall sheathing, flooring, roofing, and making durable furniture. Plywood’s strength also makes it suitable for industrial and structural applications, like formwork in construction.

Overview Comparison between Blockboard and Plywood

| Aspect | Blockboard | Plywood |

| Weight | Lightweight, easy to handle | Heavier due to the dense structure |

| Strength | Moderate strength, suitable for furniture | Superior strength, ideal for structural applications |

| Durability | Less durable, prone to warping in high moisture conditions | Highly durable, resistant to moisture and temperature changes |

| Cost | More affordable, cost-effective for large pieces | Generally more expensive |

| Manufacturing | Simpler, softwood core with veneers | More complex, with cross-laminated veneer layers |

| Uses | Interior use: furniture, shelves, doors | Versatile: interior and exterior, including flooring and walls |

| Resistance | Less resistant to moisture and temperature changes | High resistance to moisture, ideal for outdoor applications |

| Workability | Easier to cut, less prone to splitting when nailed or screwed | Can split or chip when cut improperly |

| Aesthetic | Visible knots or cracks possible, may require additional finishing | Smooth finish, minimal visible defects, often higher quality |

This table can help in quickly comparing both materials to determine the best fit for specific projects.

Conclusion: Blockboard vs Plywood – Which Should You Choose?

The choice between blockboard and plywood depends on your specific needs. If you are looking for a lightweight, cost-effective material for furniture or interior uses, blockboard is an excellent choice. However, if strength, durability, and resistance to environmental factors are critical for your project, plywood is the better option, especially for structural or outdoor applications.

Ultimately, both materials have their advantages and serve different purposes, so the decision should be based on the specific requirements of your project.