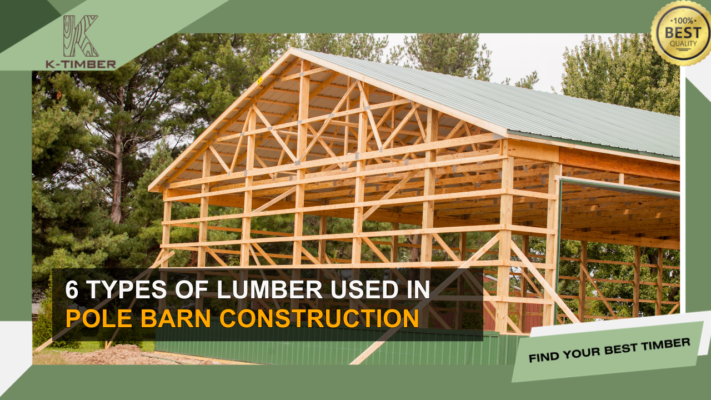

When it comes to constructing a durable and long-lasting pole barn, choosing the right type of lumber is crucial. The lumber you select will significantly impact the structure’s strength, longevity, and overall performance.

Let’s get in deeper into six types of lumber commonly used in pole barn construction, their features, and why they are preferred for specific parts of your structure.

Table of Contents

What is a Lumber Species?

Lumber species refers to the specific type of tree from which the wood is harvested. Different species have unique characteristics that influence their suitability for construction.

These characteristics include density, strength, hardness, and natural resistance to decay or insects. The wood from softwoods like pine, fir, and spruce is often preferred in construction because of its balance between strength and workability.

In contrast, hardwood species, though generally stronger, tend to be heavier and more expensive, making them less ideal for post-frame construction where affordability and ease of handling are key. Understanding the qualities of different species allows builders to choose wood that aligns with both the structural and environmental demands of the project.

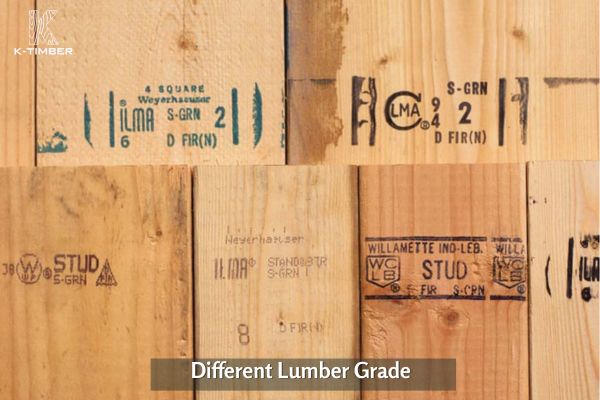

What is a Lumber Grade?

When it comes to knowing if your lumber is in high quality, there are grades to specify each of them. Let’s get in deeper into this matter so you can get a better holding of your lumber project.

Lumber grade refers to the quality of the wood based on its strength and the presence of defects like knots, splits, and grain irregularities. The grading system helps builders determine which wood is best suited for different structural components.

For example, a higher grade lumber like No. 1 or Select Structural is strong and free from major imperfections, making it ideal for load-bearing applications like posts or beams. In contrast, lower-grade lumber like No. 2 or No. 3 Common might contain more knots and splits, but it’s still suitable for non-structural or less critical components.

The grade directly affects the cost and performance of the wood. For post-frame construction, it’s important to balance the need for strength with cost-efficiency. High-grade lumber is often more expensive but offers better structural integrity, whereas lower-grade lumber is cheaper but may require additional treatment or reinforcement. Builders often use a combination of high and low-grade wood to optimize both performance and budget.

6 Types of Wood Used in Post-Frame Construction

Now that you understand what is a lumber species and how to differentiate their qualities, let’s move on to the six most popular lumber used in post-frame construction.

When selecting lumber for post-frame construction, six types of wood stand out due to their balance of strength, durability, and cost-effectiveness. Each type has its unique advantages, which makes it suitable for different parts of the structure.

1. Southern Yellow Pine (SYP)

Southern Yellow Pine (SYP) is the backbone of many post-frame constructions, especially in the southern regions of the United States. Known for its impressive strength and durability, SYP boasts a density of around 620 kg/m³, making it one of the strongest softwoods available for framing and structural applications. Its ability to bear heavy loads makes it an excellent choice for posts and beams, which are essential elements of a pole barn’s structure.

What sets SYP apart is how well it responds to pressure treatment. When treated, it becomes highly resistant to rot, decay, and insect damage, which is crucial for lumber that will be in direct contact with the ground. Its availability in large quantities also makes it a cost-effective option, allowing builders to use high-strength lumber without breaking the bank.

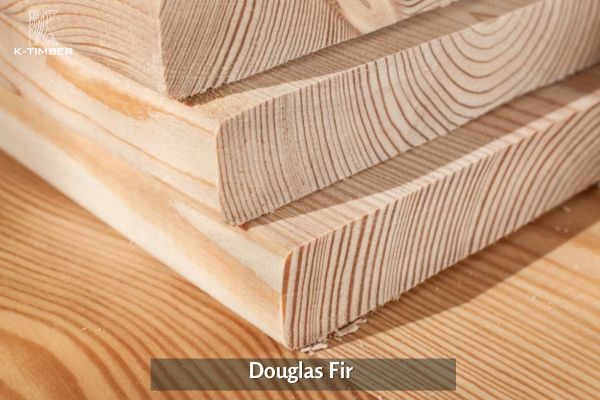

2. Douglas Fir

Another top choice for post-frame construction is Douglas Fir, which is renowned for its high load-bearing capacity and strength. With a density of approximately 530 kg/m³, Douglas Fir is slightly less dense than Southern Yellow Pine but still provides excellent structural integrity. It’s frequently used in beams, rafters, and trusses because of its ability to support significant weight without warping or twisting.

Although Douglas Fir doesn’t have the same natural decay resistance as Cedar or Redwood, it can be pressure-treated to extend its life in outdoor applications.

3. Hem-Fir

A blend of Western Hemlock and true firs, is a common alternative for those looking for affordability and ease of use. Hem-Fir has a density of around 480 kg/m³, making it lighter and easier to handle than some of the stronger woods. This makes it ideal for non-load-bearing elements or areas where weight isn’t a critical factor, such as wall framing or roof purlins.

While not as strong as SYP or Douglas Fir, Hem-Fir offers moderate strength at a lower cost, which can help reduce overall building expenses. However, Hem-Fir is not naturally decay-resistant and must be treated to withstand the elements if used outdoors.

4. Cedar

Cedar is highly prized for its natural resistance to rot and insects, which comes from the oils within the wood. With a density of around 360 kg/m³, Cedar is one of the lightest woods used in construction, making it easy to handle and install.

Even though it has low density, Cedar is incredibly durable and can last for decades without significant decay, even in harsh outdoor conditions. Its aesthetic appeal is another bonus, with rich colors and a pleasing grain pattern that adds a touch of elegance to functional structures.

Find more: Top 10 Types of Exotic Wood That You Should Explore

5. Spruce

Spruce, with a density of approximately 450 kg/m³, is another common softwood used in post-frame construction. Like Hem-Fir, Spruce requires pressure treatment if used in exterior applications to resist rot and insect damage. Spruce is especially favored in colder climates, as its availability and affordability make it a cost-effective option for builders looking to stretch their budgets without sacrificing quality.

6. Redwood

Redwood is a premium wood known for its natural durability and resistance to decay and insects. Its density of around 450 kg/m³ places it in the middle range for softwoods, offering a good balance between strength and weight. Redwood’s natural oils protect it from moisture, making it a top choice for outdoor applications like siding and decking.

We hope after this blog, you can understand more and can make good choice for your next pole barn construction. If you are looking for high quality African hardwood, then K-Timber is a great choice for you. Providing the best services with competitve price for all our customers. Contact us now for more information.

![[K-Timber] Blog Post Boder (7)](https://k-timbers.com/wp-content/uploads/2024/07/K-Timber-Blog-Post-Boder-7.png)