Moisture content is an important factor that affects the quality, durability, and usability of wood. Too much moisture can cause wood to warp, crack, and rot, while too little moisture can cause wood to shrink and crack. So how to determine wood moisture? In this article, K-TIMBER will introduce current popular methods of determining wood moisture as well as necessary notes for accurate measurement.

Table of Contents

What is the moisture content of wood?

The moisture content of wood refers to the amount of water present in the wood compared to the weight of the dry wood. It’s expressed as a percentage, and the ideal moisture content for wood used in construction or furniture making generally falls between 8% and 12%. According to our long-term experience and knowledge in the industry, let’s look at 4 ranges of wood moisture content and their meaning:

- Freshly cut wood: 40% to 200% moisture content. This high moisture content makes the wood unsuitable for most uses as it can shrink, warp, and crack as it dries.

- Air-dried wood: 15% to 20% moisture content. This is achieved by slowly drying the wood outdoors over several months. Air-dried wood is suitable for some non-critical applications, but it may still move slightly as it adjusts to the ambient humidity.

- Kiln-dried wood: 6% to 8% moisture content. This is the most common type of wood used for construction and furniture making. Kiln drying is a faster and more controlled process than air drying, and it results in wood that is more stable and less prone to movement.

- Moisture equilibrium content (EMC): The moisture content at which wood will neither gain nor lose moisture from the surrounding air. The EMC of wood depends on the relative humidity and temperature of the air. For example, wood in a room with 50% relative humidity will have an EMC of about 10%.

Humidity vs Moisture Content – What’s the difference?

Humidity and moisture content might sound similar, but they have distinct meanings in the context of air and materials like wood. Here’s how they differ:

| FEATURE | HUMIDITY | MOISTURE CONTENT |

| Definition | Amount of water vapor present in the air | Amount of water present in a material compared to its dry weight |

| Units | Relative humidity (%) | Percentage (%) |

| Measured with | Hygrometers, humidity sensors | Moisture meters, weight-based methods |

| Factors affecting it | Temperature, air pressure, weather conditions | Temperature, surrounding humidity, material properties |

| Impact on materials | Influences moisture content of materials like wood, paper, textiles | Directly affects material properties like strength, stability, susceptibility to warping, cracking, and decay |

| Relation to each other | High humidity can increase moisture content if materials are exposed for long periods | Low humidity can cause drying and lower moisture content |

How Do You Remove Moisture From Wood?

Freshly cut wood typically has a very high moisture content. However, this moisture content will naturally evaporate over time in the air. Excessive moisture leads to warping, cracking, and even rotting of the wood, making it unsuitable for most uses. To combat this, a controlled and efficient method called kiln-drying has been developed.

Kiln-drying is the process of artificially removing moisture from wood using a specialized chamber called a kiln. Unlike the slow and unpredictable nature of air drying, kiln-drying allows for precise control of temperature, humidity, and air circulation, resulting in a faster and more consistent drying process.

Some of the unfinished wood you see on the market has been kiln-dried to reduce its moisture content to around 8%. This helps to prevent moisture-related defects such as warping and buckling. However, many building materials may have been dried to about 15% moisture content.

Kiln-drying creates an environment that helps wood dry quickly and uniformly, reducing the risk of defects such as warping and cracking. Additionally, kiln-dried lumber is significantly more stable, exhibiting minimal shrinkage or expansion after installation, making it ideal for use in construction and furniture making.

What are Acceptable Moisture Levels in Wood?

The acceptable moisture level in wood depends on several factors, including its intended use and the environment it will be exposed to. Typically, the acceptable moisture content of lumber ranges from 8-15% for weather-resistant and rot-resistant interior or exterior wood.

Why you need to determine the moisture content of wood?

By understanding the impact of humidity on wood properties, we can ensure wood stability, durability and longevity. So, why exactly is knowing the moisture level of wood so important?

- Ensuring Stability and Avoiding Deformation: When moisture content is too high, wood swells, leading to warping, cracking, and even structural failure. Contrary, when it’s too low, wood shrinks and becomes brittle, susceptible to splitting and breakage. Determining the moisture content allows us to predict and prevent these potentially disastrous transformations, ensuring the stability and longevity of our wood projects.

- Preserving Strength and Integrity: High moisture content weakens wood, reducing its load-bearing capacity and making it more hazardous to damage. This is particularly crucial for structural applications like beams and joists. By measuring content, we can ensure the wood used in such critical components possesses the necessary moisture strength and integrity to carry the required loads, preserving the structural integrity of our constructions.

- Preventing Decay and Rot: Moisture is the lifeblood of wood-destroying fungi and bacteria. When the content is high, these organisms thrive, causing rot and decay, compromising the structural integrity and aesthetic appeal of wood.

- Achieving Precision and Avoiding Waste: Woodworking often involves intricate cuts and joins. Improper content can cause dimensional changes, leading to misaligned pieces and wasted moisture materials.

Some ways to measure Moisture Content in Wood?

How to check moisture content of wood without meter?

Accurately gauging the moisture content (MC) of wood is crucial for any project, from furniture crafting to building sturdy decks. According to ASTM (American Society for Testing and Materials) standard D4442, there are two alternative methods of hygrometer: drying oven method and distillation method.

Using wood drying oven

The drying technique is a method used to determine the moisture content of wood by drying a small sample. This process uses the difference in weight of wood before and after drying to determine moisture content. Specifically:

- Take a small sample and make sure it fits inside the oven. Weigh wood using an accuracy scale specified by ASTM D4442.

- Place the sample in a forced convection oven at temperatures between 215°F and 220°F (102°C and 105°C), as recommended by the National Wood Flooring Association. The oven must maintain a temperature of 103 ± 2°C throughout the drying chamber and allow moisture to escape.

- Monitor the weight of the wood at regular intervals, continuing the drying process until the weight stabilizes over a period of 4 consecutive hours.

- Weigh the wood again after the drying process is complete.

- Calculate humidity using a specific formula

Although oven drying can be used as an alternative method for measuring moisture when other options are not available, it has several disadvantages. Specialized tools, such as accurate scales and a well-ventilated wood stove, are necessary and may incur additional costs compared to purchasing a quality moisture meter.

Furthermore, the process is labor-intensive and time-consuming, comparable to the time required to repair or replace a moisture meter. In addition, this method also causes the wood sample to be destroyed.

The distillation method

The distillation method is employed in laboratory environments to assess the moisture content of wood subjected to “chemical treatment or impregnation.” This technique is particularly suitable for wood treated with preservatives or chemicals that might compromise the precision of alternative measurement methods.

To implement this approach, a representative wood sample is obtained and cut into chips, typically ranging from 20 to 50 grams. These wood chips are then placed in a heated flask, to which a chemical solvent, typically xylene or toluene, is added. The solvent induces the evaporation of water from the wood chips, and an external cooler condenses the evaporated water. The collected condensed water is subsequently quantified to determine the moisture content in the original wood chips.

In reality, it is not feasible for a woodworker. As you likely lack the scientific equipment such as a flask, a chemical solvent, and a specialized cooler for water condensation, this method is beyond the scope of typical woodworking activities.

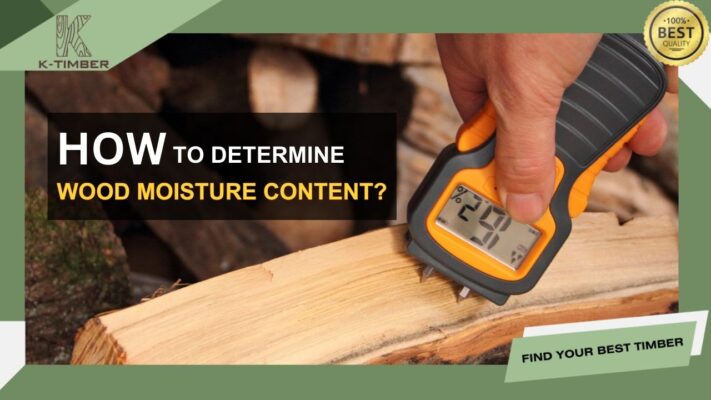

Use Moisture Meter Testing

While the oven-dry method can be a reliable way to measure moisture content, a moisture meter often presents a better option for most situations, thanks to its numerous advantages.

Unlike the oven-dry method that destroys the sample, most moisture meters are non-invasive. They can measure content without damaging the material, making them ideal for situations where preserving moisture in the sample is important.

Furthermore, meters provide quick and easy measurements, often in just a few seconds, and offer exceptionally high accuracy rates. This is a significant advantage over the oven drying method, which can take several hours or even days.

While the oven-dry method has its place as a reference standard, a moisture meter provides a faster, more convenient, and non-destructive approach to moisture measurement. Its versatility, accuracy, and cost-effectiveness make it the preferred choice for most situations across various industries and applications.

However, the problem here is that wood suppliers and wood buyers often cannot agree on the type of machine to use and create discrepancies in the purchasing process. So which type of wood moisture meter is best to choose?

Recommend the best MC Testing machine for wood buyer

To address the issue of inconsistency in the type of wood moisture meters used and the resulting discrepancies in the purchase process, K-TIMBER encourages wood suppliers and buyers to adopt the use of Wagner wood moisture meters for the following reasons:

- High accuracy: Wagner wood moisture meters are designed to provide high accuracy, even for complex wood species. The meters use IntelliSense™ technology to measure moisture deep within the wood, allowing us to obtain more accurate results than other moisture meters that only measure surface moisture.

- Ease of use: The design is easy to use, even for inexperienced users. The meters have a large, clear LCD screen, clear instructions, and an automatic setting for most wood types.

- Versatility: Wagner wood moisture meters can be used to measure the moisture content of a variety of wood species, including hardwoods, softwoods, plywood, and composite wood.

We understand that the moisture content of wood is an important factor for many applications, from construction to interiors. Wood that is too wet can warp, crack, and split, while wood that is too dry can be prone to cracking and breaking.

Finding a reliable wood supplier that can provide wood with the appropriate moisture content can be a challenge. That’s why we’re here to help. At K-TIMBER, we are committed to providing our customers with accurate and high-quality wood with the right moisture content. With over 20 years of experience and industry knowledge, we understand your needs and ensure that you receive the right wood for your project.

If you are looking for a wood supplier that can help you find the right wood with the right moisture content, contact K-Timbers today. We guarantee that you will receive the perfect wood for your project.

![[K-Timber] Blog Post Boder](https://k-timbers.com/wp-content/uploads/2024/07/K-Timber-Blog-Post-Boder-4.jpg)