In addition to absorbing and losing moisture in the air, wood also has another property, which is shrinkage. This is one of the most common defects in both natural and engineered wood. Understanding the shrinkage of wood helps to avoid cracking, warping, and other defects in finished products during use. So, what is the shrinkage of wood and how to fix it? Let’s find out more about this phenomenon as well as the shrinkage considerations when buying wood in Africa in the following article.

Table of Contents

Definition of shrinkage in wood

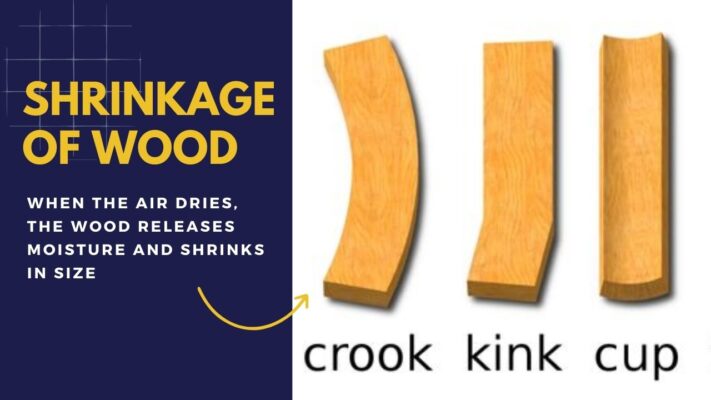

Wood shrinkage is the natural process by which wood loses moisture and shrinks in size. This happens because wood is a hygroscopic material, meaning it absorbs and releases moisture from the surrounding environment. When the surrounding air is humid, wood absorbs moisture and swells. Conversely, when the air is dry, wood releases moisture and shrinks. This natural process primarily occurs across the grain, meaning the width and thickness of the wood are more affected than its length.

Major issues of shrinkage in wood

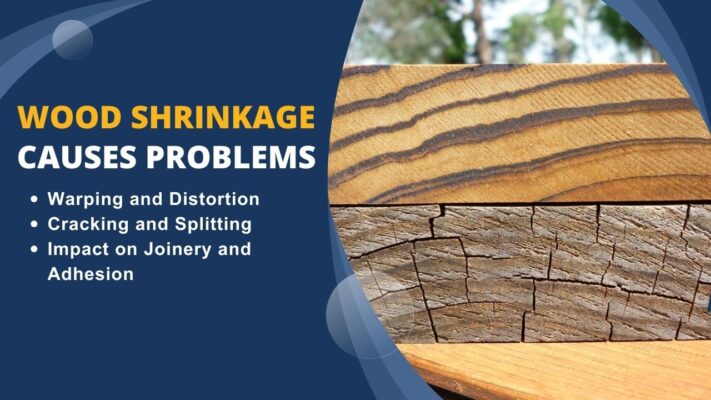

The moisture content of wood is an important factor that affects its size. Changes in humidity lead to dimensional changes that cause the wood to shrink, deform and lose structural stability.

- Warping and Distortion: Shrinkage often manifests as warping and distortion in wood products. Warping can take various forms, including cupping, bowing, twisting, and crooking. These distortions not only compromise the aesthetic appeal of wood products but also affect their functionality and structural integrity.

- Cracking and Splitting: Another significant issue associated with shrinkage is the formation of cracks and splits in the wood. As the wood undergoes shrinkage, internal stresses build up, leading to the formation of cracks. These cracks can occur both radially and tangentially, compromising the strength of the wood and reducing its overall durability. Cracking is particularly problematic in applications where the structural integrity of the wood is crucial, such as in construction.

- Impact on Joinery and Adhesion: Shrinkage can also pose challenges in woodworking joinery and adhesion. In situations where wood components are joined together, changes in dimensions can create gaps or loosen joints. This can affect the overall stability and longevity of the assembled structure.

What is the cause of wood shrinkage?

One of the main causes of wood shrinkage is uncontrolled humidity. When wood is not properly treated to achieve moisture balance with the end-use environment, it can absorb or lose water quickly when introduced into a new environment. This leads to rapid dimensional changes, causing warping, distortion, and cracking.

In addition, storing wood outside before bringing it into the workshop can also cause shrinkage. When wood is stored offsite, it can absorb moisture from the peripheral environment, and when put into another environment in the workshop, it needs a period of time to adapt. Without moisture control and insufficient acclimatization time, wood can experience shrinkage and other related problems. Besides, some other causes leading to shrinkage of wood include:

- Wood Species: Different wood species exhibit varying shrinkage rates and magnitudes. Hardwoods generally have a higher density and, accordingly, tend to shrink more than softwoods. The cellular structure of hardwoods, with smaller and more tightly packed cells, contributes to their higher susceptibility to shrinkage.

- Grain Directions: Shrinkage is not uniform in all directions. It is most significant across the grain (radial and tangential directions) compared to along the grain (longitudinal direction). The arrangement of wood fibers and cells makes it easier for the wood to contract along the length of the grain than across it. This characteristic issue is crucial to consider when designing and working with wood to minimize potential associated with shrinkage.

- Drying Conditions: The drying process significantly influences wood shrinkage. Rapid or uneven drying can lead to excessive and uneven shrinkage, resulting in issues such as warping, twisting, and cracking. Proper drying conditions, including controlled temperature and humidity, are essential to ensure that the wood dries uniformly.

Calculating Dimensional Changes in Wood

While wood is naturally stable when fully saturated with water, it shrinks or expands as it dries due to the loss or absorption of bound water within its cell walls. This movement is most pronounced across the annual growth rings (tangentially), about half as much across the rings (radially), and minimal along the grain (longitudinally).

The extent of shrinkage in each direction, expressed as a percentage of the original size when freshly cut, varies considerably between wood species. As a general rule, expect roughly 8% tangential shrinkage, 4% radial shrinkage, and 0.1% longitudinal shrinkage when drying from fresh to completely dry. Denser woods tend to shrink more than lighter ones.

For woodworkers, this means accounting for wood movement, particularly across the width of boards. Most boards are “flat-sawn,” meaning their faces run along the growth rings, leading to significant width changes with moisture fluctuations. “Quarter-sawn” boards, with growth rings perpendicular to the faces, are much more stable in width but may exhibit greater thickness changes, which are often less noticeable due to their typical wider dimensions.

To estimate the dimensional changes a wood piece will undergo due to moisture content changes (below the fiber saturation point), you can use the following formula:

This formula helps woodworkers choose the right cuts and construction methods for their projects, ensuring their creations stay true and functional over time.

Note when buying wood from Mozambique, Congo & Niger

Wood from Mozambique, Congo, and Niger is often attractive to buyers due to its cost-effectiveness. However, consumers need to be aware of the potential challenges associated with the processing, drying, and preservation of wood from these countries. Despite the initial affordability, issues such as warping, discoloration, and degradation can arise over time. Additionally, wood purchased from these sources may require additional time and care before it can be used effectively in construction, interior design projects in general, and projects in Vietnam in particular.

- Wood quality and processing: Wood from Mozambique, Congo, and Niger is often praised for its affordability, making it an attractive option for buyers. However, the cost-effectiveness comes with potential limitations associated with the processing methods used in these regions. Drying and preservation techniques may not meet international standards because these countries often process and dry wood within a week, which can stress the wood and affect its internal structure.

- Concerns about shrinking: One of the main challenges associated with wood from these regions is its tendency to shrink over time. Uneven drying with a moisture content of 25-35% and in a short period of time can lead to uneven moisture content in the wood, leading to warping, twisting, and cracking. Buyers should be cautious and note that the initial cost savings may be greater due to the need for additional processing or adjustment to counteract the effects of shrinkage.

- Discoloration and degradation: In addition to shrinkage, wood from Mozambique, Congo, and Niger can also have issues such as fading, discoloration, and overall degradation. The lack of standard processing procedures can contribute to changes in the quality of the wood, affecting the aesthetic and structural integrity of the wood. Buyers should carefully inspect the wood for signs of discoloration or deterioration before making a purchase decision.

- Waiting time before use: Wood from these regions may need a waiting period when it arrives in Vietnam or other importing countries before it can be used effectively. The wood may need time to adapt to the local environment and stabilize moisture for about 1 to 2 months before it can be sawn. This can have a significant impact on the progress of projects with high time requirements.

While wood from Mozambique, Congo, and Niger offers a cost-saving option for buyers, it is important to be aware of the potential challenges associated with the processing, drying, and preservation activities in these regions. Warping, discoloration, and degradation are common problems that can arise if appropriate preventive measures are not taken.

So where should you buy wood to avoid problems with wood shrinkage?

So, where to buy wood that ensures both quality and moisture content is a major challenge for today’s buyers. However, Angola and Cameroon are two countries emerging as ideal destinations for those looking for high-quality and stable wood sources.

Angola and Cameroon are two countries located in the West African region, with abundant and diverse forest resources. The woods here are highly valued for their quality, durability, and aesthetics. In particular, some types of wood such as Mussivi, Doussie, Iroko, Pachyloba, Sapele, Ayaba, etc have good shrinkage and warping resistance, making them very suitable for applications requiring high stability such as interior, exterior, industrial, etc.

In addition to good wood quality, Angola and Cameroon also have modern wood production and processing processes, ensuring that the moisture content of the wood is at a balanced level before being marketed. This helps to minimize the risk of shrinkage and warping of wood after use.

In addition to excellent wood quality, Angola and Cameroon also apply modern wood production and processing processes. Before being marketed, these types of wood are controlled for moisture content to ensure that they are at a balanced level. This plays an important role in minimizing the risk of shrinkage and warping of wood after use. This process not only increases the stability of the wood but also ensures that the final product meets the high quality requirements of customers.

With the combination of good raw materials, modern production processes, and stable quality, wood from Angola and Cameroon is becoming a priority choice for manufacturers, artisans, and consumers interested in using wood with high reliability in construction and production projects.

![[K-Timber] Blog Post Boder (1)](https://k-timbers.com/wp-content/uploads/2024/06/K-Timber-Blog-Post-Boder-1.jpg)

![[K-Timber] Blog Post Boder](https://k-timbers.com/wp-content/uploads/2024/06/K-Timber-Blog-Post-Boder.jpg)