The treatment of natural wood before it becomes finished wood is one of the most crucial steps, directly affecting the quality, durability, and beauty of the product. However, few are aware that the natural wood processing methods in different countries hide many interesting secrets. In the following article, K-TIMBER will reveal to you the intriguing details hidden behind the natural wood processing procedures in various African countries. Let’s explore!

Table of Contents

Why Natural Wood Needs to Be Treated

Before delving into the secrets hidden within the natural wood processing procedure, let’s understand the significance of treating natural wood. So, why is the treatment of natural wood important?

- Moisture Removal: Fresh natural wood contains high moisture levels, making it prone to warping, bending, and mold. Therefore, the processing procedure helps eliminate moisture and harmful agents, ensuring durability and stability for wood products, whether for high-end furniture or construction.

- Enhancing Durability and Lifespan: Treatment prevents wood from shrinking, cracking, warping, and other common issues due to moisture changes. This process increases the usability lifespan and saves long-term costs.

- Improving Water Resistance and Pest Resistance: Treating wood with specialized chemicals prevents termite and insect attacks. This prolongs the wood’s lifespan and ensures durability for wood products.

Natural Wood Treatment Methods

Currently, there are countless natural wood treatment methods employed by various wood suppliers. At K-TIMBER, we choose the natural wood kiln-drying method to ensure safety for users. However, some other wood suppliers prioritize profit and resort to chemical impregnation, which can quickly lead to wood cracking, breaking, and warping.

Natural Air-Drying Method

Treating wood using the natural air-drying method is a traditional approach that K-TIMBER has always prioritized for many years. This method utilizes sunlight and wind to dry the wood. The process usually takes several weeks or even months, depending on the type of wood and weather conditions.

However, according to K-TIMBER, an expert in the wood industry, this drying method only removes 80-85% of the water content in the wood.

- Advantages: Low cost, no need for expensive equipment, and environmentally friendly.

- Disadvantages: Long drying time, inability to precisely control the surrounding environment, and the risk of termite or mold infestation during the drying process.

Superheated Steam Drying Method

Besides the natural air-drying method, another popular approach currently is superheated steam drying. This involves drying wood at temperatures above 100 degrees Celsius (typically around 110 degrees Celsius). As a result, the water in the wood changes from liquid to vapor, creating a pressure differential between the wood cells and the environment, facilitating the outward movement of moisture.

- Advantages: Quickly dries wood, applicable to many types of wood, minimizes the risk of deformation and cracking, and reduces the likelihood of microbial attacks.

- Disadvantages: Higher equipment and operational costs compared to natural air drying, and requires precise techniques to avoid damaging the wood.

Condensing Moisture Drying Method

The condensing moisture drying method is often applied to hard and thick woods, drying them at low temperatures.

Initially, the wood pieces are placed in a drying oven at high temperatures, where all the hot and moist air is drawn into a cooling coil and condensed into water, which is then expelled outside. Subsequently, the cold air with low moisture content is reheated, causing the wood to be thoroughly dried from the inside out.

- Advantages: Good control over the drying environment, minimizing the risk of cracking and deformation due to uneven moisture loss.

- Disadvantages: Requires specialized equipment and has relatively high operational costs.

Vacuum Drying Method

This method relies on the boiling point of water and pressure, creating a difference between the pressure inside and outside the wood. By reducing the pressure in a vacuum environment, the moisture in the wood evaporates, and the wood gradually dries.

- Advantages: Saves labor, automates moisture control, and can maintain the wood at the required moisture level.

- Disadvantages: Time-consuming, resource-intensive, and unsuitable for drying large quantities.

Secrets About Natural Wood Drying Methods in African Countries

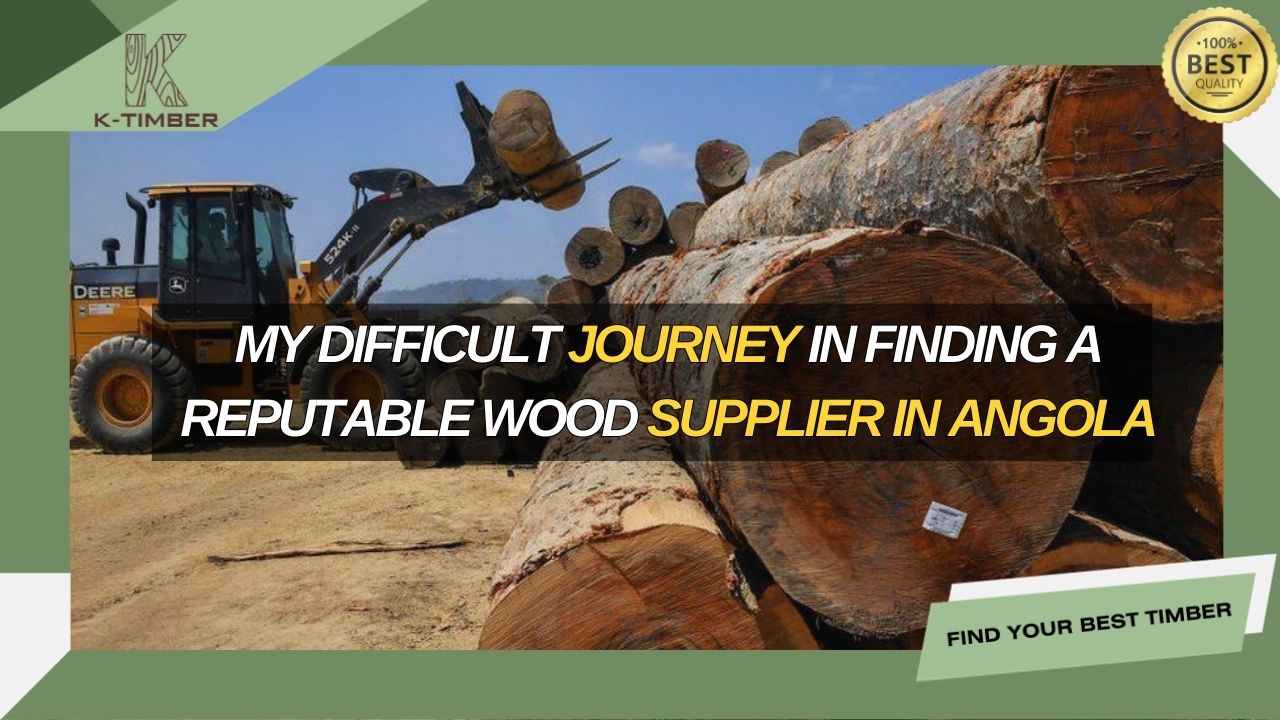

As a specialist in the global production and supply of raw wood materials, K-TIMBER has engaged with thousands of customers worldwide, backed by over 20 years of industry experience. We understand that the wood processing procedure needs to be conducted with care and precision to ensure the best wood quality.

However, after years of working and exploring wood processing procedures across many countries, we’ve found that not every nation employs advanced and efficient wood drying methods.

In some African countries like Mozambique, Congo, and Niger, to minimize costs, wood is only dried to a moisture content of 20 – 35% within a week, compared to the two-week standard at K-TIMBER and international regulations. This significantly impacts the pressure balance between the wood cells and the external environment, leading to rapid warping and cracking of the wood.

K-TIMBER always leads in applying modern wood drying technologies that meet international standards, ensuring wood moisture content is <20%. Our wood is evenly dried, preserving its natural color and grain while enhancing durability and resistance to termites.

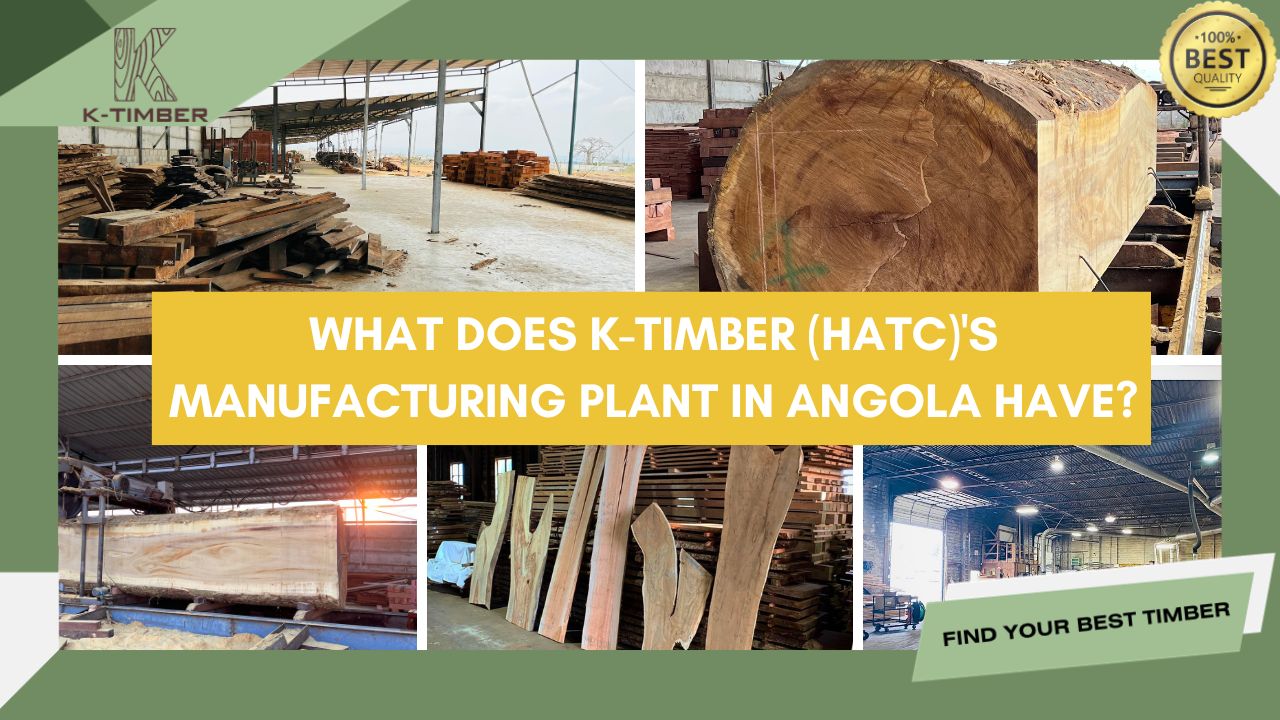

With a team of experienced technicians and a modern machinery system equipped in all 5 of our workshops, we are confident in offering our customers high-quality raw wood materials at prices 20% lower than the market.

READ MORE: Why is wood from Mozambique, Congo, Niger cheaper than Angola & Cameroon?

Contact K-TIMBER for consultation and the best quotes:

- ADDRESSS VIET NAM (K-TIMBER): 169 Nguyen Ngoc Vu street, Cau Giay District, Hanoi.

- Phone: (+84) 833333914

- Email: [email protected]

![[K-Timber] Blog Post Boder](https://k-timbers.com/wp-content/uploads/2024/07/K-Timber-Blog-Post-Boder-2.png)

![[K-Timber] Blog Post Boder (1)](https://k-timbers.com/wp-content/uploads/2024/06/K-Timber-Blog-Post-Boder-1.jpg)