For construction engineers, choosing wood for underwater purposes may seem unwelcome, but for architects and users, the application of wood in this case is truly a breakthrough in aesthetics and cost. With over 100,000 types of wood, if we use the wrong type underwater it can be a disaster with structural risks and repair costs. To satisfy the interest of project-owners, K-Timber will list the top 5 types of underwater wood.

Table of Contents

The Underwater Environment: A Hostile Challenge

The underwater environment is a demanding condition where few materials can endure. Constant submersion, immense pressure, and the relentless assault of saltwater create a hostile environment that rapidly degrades most substances. To exist this unforgiving domain, wood must possess extraordinary characteristics:

- Water resistance: Prevents rot and swelling, protecting the structural integrity of the wood.

- Pressure resistance: The ability to withstand high water pressure without warping is essential to maintain the shape and load-bearing capacity of the wood.

- Penetration resistance: The wood being hard enough to resist attack from marine organisms is important in protecting the wood from internal and external damage.

- Corrosion resistance: Immunity to the corrosive effects of salt water is paramount to preserving the durability of the wood and preventing deterioration over time.

Top 5 Types of Wood to Used Underwater

Iroko

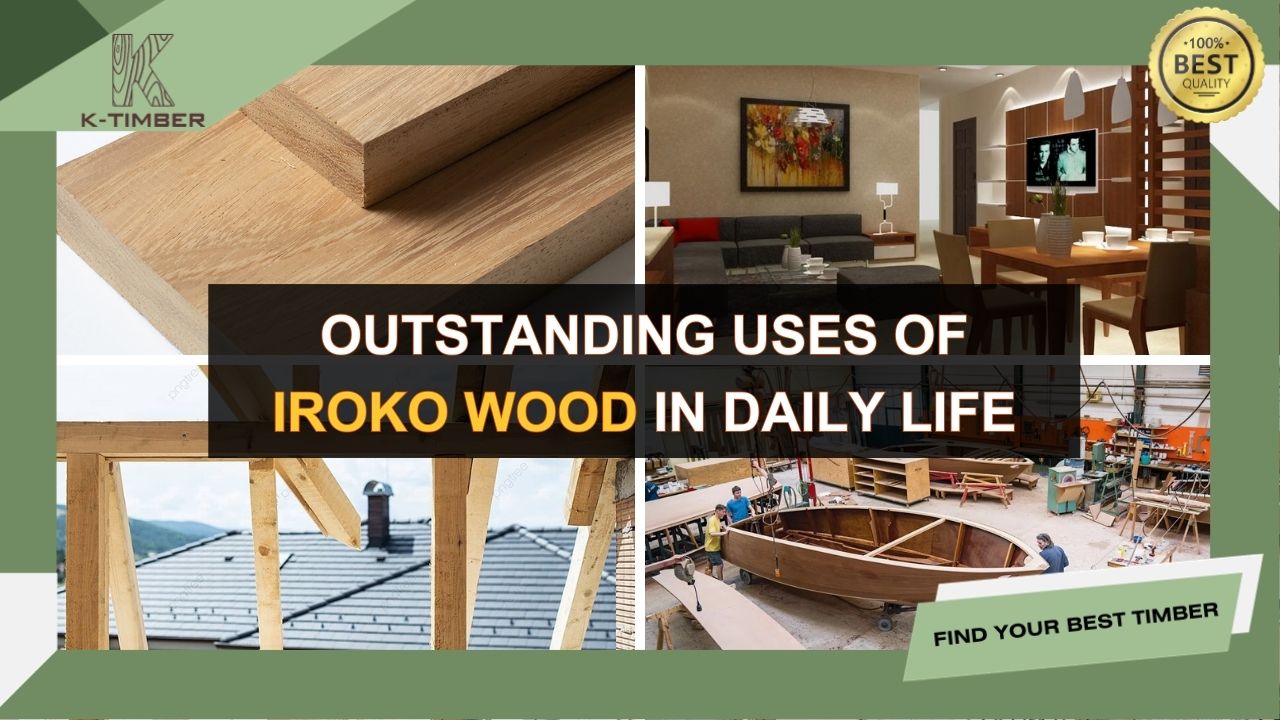

Iroko, also referred to as “African Teak,” is a hardwood that is indigenous to tropical Africa’s western region and is highly valued for its resilience to rot and decay. While iroko is more affordable than teak wood, it shares many of the same physical characteristics. It is an excellent option for subsea applications because of its natural oils, which provide it exceptional resistance to marine borers and other pests.

Iroko is a medium-textured, thick hardwood with a lovely and unique grain pattern. The wood has a spectrum of colors, from yellow to medium brown, which darkens with time. Its superior resistance to wear and abrasion is a result of its density and interlaced grains.

For decks, hull construction, and interiors, roko is ideal. Because of its hardness and inherent oils, the wood is ideal for boat decking. It is resilient to prolonged contact to sea water and high loads. Its lifetime in maritime situations is ensured by its resistance to rot and resilience, which make it ideal for hull planking. The boat’s interior is made more elegant by the wood’s appealing hue and texture.

Acajou

Native to Central and West Africa, acajou is sometimes called African mahogany. This kind of wood is widely valued for its stunning reddish brown color, solidity, and longevity. Because of its superior machining and finishing qualities throughout the manufacturing process, Acajou wood is frequently used in boatbuilding for both structural and ornamental aspects.

Acajou has medium to coarse texture and straight to interlaced grain. With age, the heartwood’s hue progressively darkens from pale pink to reddish brown. This medium-thickness wood provides an excellent mix of strength and weight.

Acajou is best used for trim, internal joinery, and hull panels. Acajou has a robust and visually appealing finish, making it the perfect material for hull building due to its strength and stability. Carpenters frequently choose Acajou because of its lovely finish and simplicity of processing for creating interior panels, cabinets, and other woodwork. The rich color and fine texture of acajou make it a perfect material for ornamental components that elevate the boat’s external and interior design.

Mukulungu

Mukulungu is a Central African native that is highly valued for its hardness and density, which makes it a great material for boat structural components. Mukulungu is appropriate for maritime situations because to its inherent resistance to termites and rot. Being one of the few woods that is really suited for maritime situations, mukulungu is highly valued for its remarkable strength and endurance. The longer it is submerged in water, the harder it gets.

Mukulungu is a hefty, solid wood with straight to interlaced grain and a fine to medium texture. When exposed to light, the heartwood’s color darkens, ranging from reddish brown to purple brown.

Ship keels, frames, and ribs are good applications for Mukulungu. Because of its strength and density, mukulungu is perfect for use as a keel, giving the boat a sturdy base. Mukulungu wood is known for its toughness, which makes it suitable for frames that need to survive the harsh conditions of the sea. Because of mukulungu’s hardness and resistance to decay, it may be used for ribs without compromising the boat’s structural integrity.

Cedar

Because cedar, particularly Western Red Cedar, is naturally resistant to decay and insects and lightweight, it is highly prized. This North American natural wood is well-known for its delightful scent, which deters pests. It is also quite simple to work with, which makes it a fantastic option for a variety of boat parts.

Cedar has a unique, pleasant scent, straight grain, and a homogeneous feel. The wood’s hues vary from light yellow to a rich reddish-brown. It is a lightweight material with strong sound-dampening and thermal insulation qualities.

For planking, decking, and canoe and kayak construction, cedar is ideal. Because of its low weight and decay resistance, it is perfect for hull planking, keeping vessels strong and afloat. Cedar is an excellent material for decking because of its durability and natural beauty, which provide a lovely and pleasant surface. Cedar is also a common material for smaller boats, such as canoes and kayaks, due to its buoyancy and simplicity of maintenance.

Douglas Fir

Douglas Fir is widely recognized for its exceptional strength-to-weight ratio and ability to withstand decay with proper care. Because it is easily accessible and reasonably priced, this native North American material is frequently employed in boat construction. This wood is adaptable and may be used for both structural and non-structural purposes.

Douglas Fir has a medium to coarse feel and a straight grain. It might be pale yellow or reddish-brown in hue. It’s a robust, medium-weight wood with an excellent strength-to-workability ratio.

For masts, spars, and structural parts, Douglas Fir is perfect. since of its strength and flexibility, it is ideal for masts since it gives sails the support they need. Douglas Fir spars are known for their exceptional strength-to-weight ratio, which makes them very resilient to the rigors of sailing. Furthermore, Douglas Fir’s resilience makes it a good choice for ribs and other structural pieces like frames.

Maximizing the Lifespan of Underwater Wood

To ensure the longevity of your underwater wood project, consider these essential factors:

- Protective Coatings: Apply marine-grade wood preservatives to enhance resistance to decay and marine organisms.

- Corrosion-Resistant Fasteners: Use stainless steel or other suitable materials to prevent metal failure.

- Expert Design and Construction: Optimize the wood’s performance through careful planning and execution.

Conclusion

Selecting the right wood for underwater applications is crucial for the success of any marine project. By understanding the unique challenges of this environment and leveraging the exceptional properties of specific wood species, you can create structures that not only endure but thrive underwater.

Buy Quality, Affordable Iroko Wood at K-TIMBER

Are you looking for a reputable supplier of Iroko wood, offering quality at a reasonable price? K-TIMBER is the perfect choice for you. With over 20 years of experience in the timber export industry and successful exports to over 30 countries worldwide, we have established ourselves as a leading provider of quality Iroko wood.

Should you buy Iroko wood at K-TIMBER?

- Top-Quality Wood: K-TIMBER is committed to providing Iroko wood, and other African hardwoods, to the FAS (First and Seconds) grade standard, ensuring up to a 90% yield of high-quality, defect-free wood—free from warping, cracking, heartwood issues, sapwood, and pests, thus guaranteeing a durable and high-quality wood supply for our customers.

- Sustainable Origin: Building a close relationship with the Angolan government, K-TIMBER guarantees a supply of quality wood, sustainably sourced from tropical forests and fully certified by the FSC (Forest Stewardship Council).

- Competitive Pricing: Along with quality, K-TIMBER is confident in offering our customers Iroko wood at prices 20% lower than the market rate. We supply up to 20,000 cubic meters of wood each month.

- Customer Service: The quality of our customer service is also a key factor in the success of K-TIMBER. Our team is always ready to assist and answer any questions from customers 24/7, despite the different time zones in each country.

![[K-Timber] Blog Post Boder](https://k-timbers.com/wp-content/uploads/2024/07/K-Timber-Blog-Post-Boder-3.png)