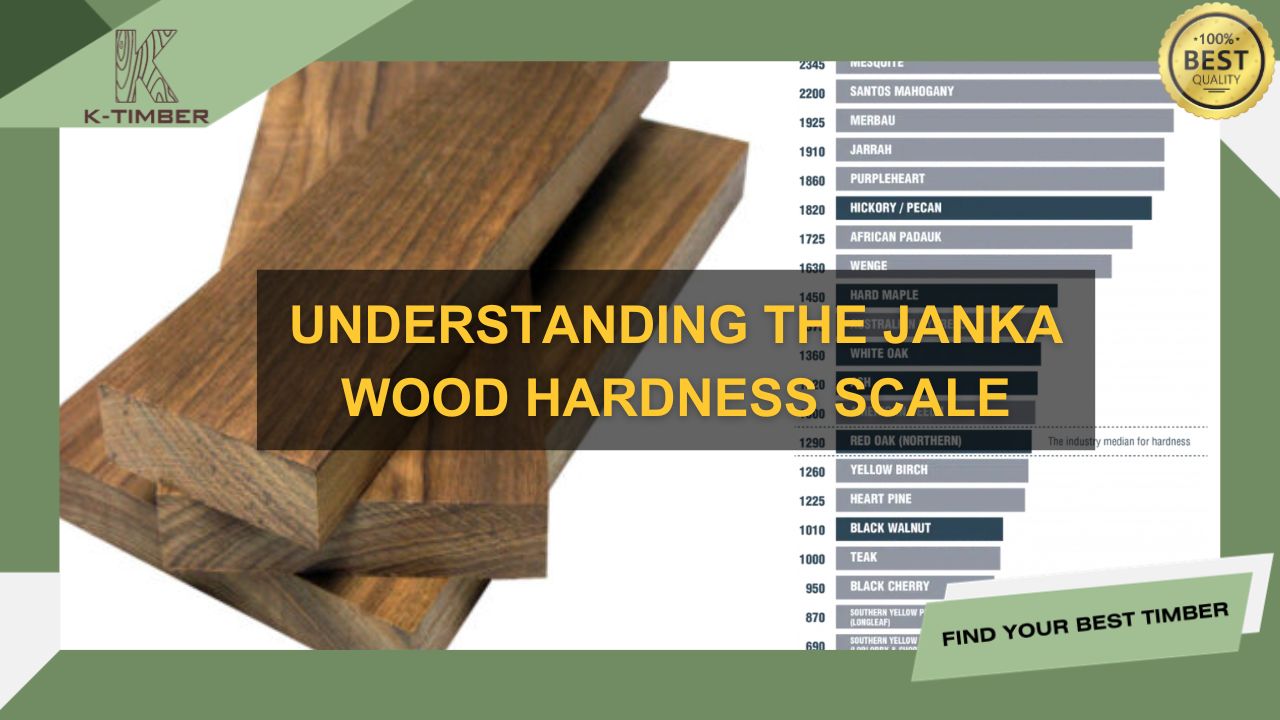

Choosing the appropriate wood material for interior projects is a crucial decision that requires careful consideration of various factors. Among these factors, hardness and durability are always top priorities. You may be wondering, how is the hardness of wood measured?

The answer lies in the Janka Wood hardness scale. This internationally recognized measurement tool helps to accurately determine the resistance to scratches, dents, and general wear and tear of a specific wood species. In this article, K-TIMBER will delve deeper into the Janka hardness scale and its significance in selecting the ideal wood material for your next interior project.

Table of Contents

What is the Janka Scale?

The Janka Wood hardness scale is a system of numerical values that statistically represents the density of wood after undergoing a specific testing procedure. It indicates a wood species’ ability to resist surface indentation, denting, and wear and tear based on the test results.

Developed by Austrian-American researcher Gabriel Janka in the early 20th century, the Janka scale utilizes different units of measurement:

- Pound-force (lbf) in the United States

- Kilogram-force (kgf) in Sweden

- Newton (N) or kilonewton (kN) in Australia

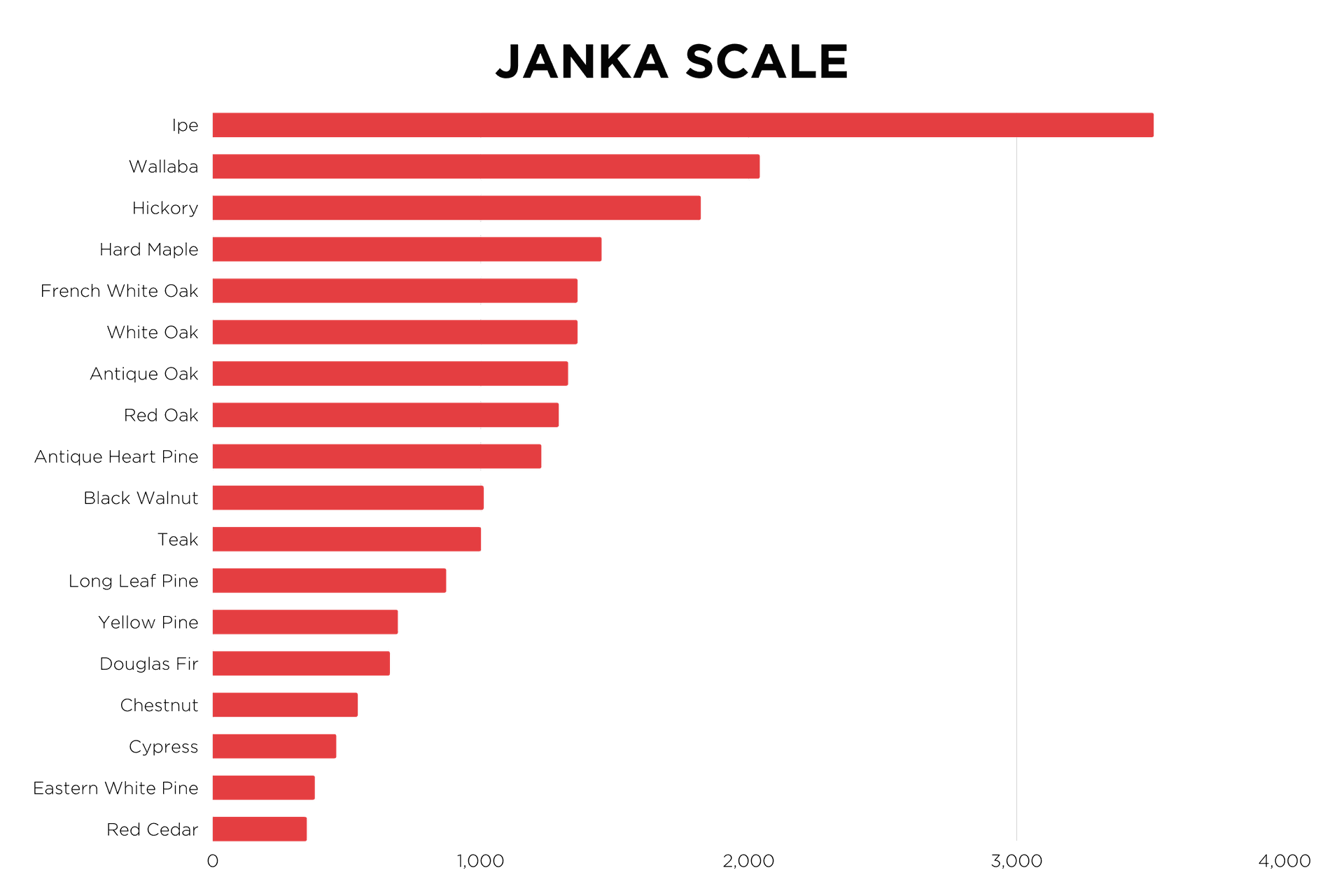

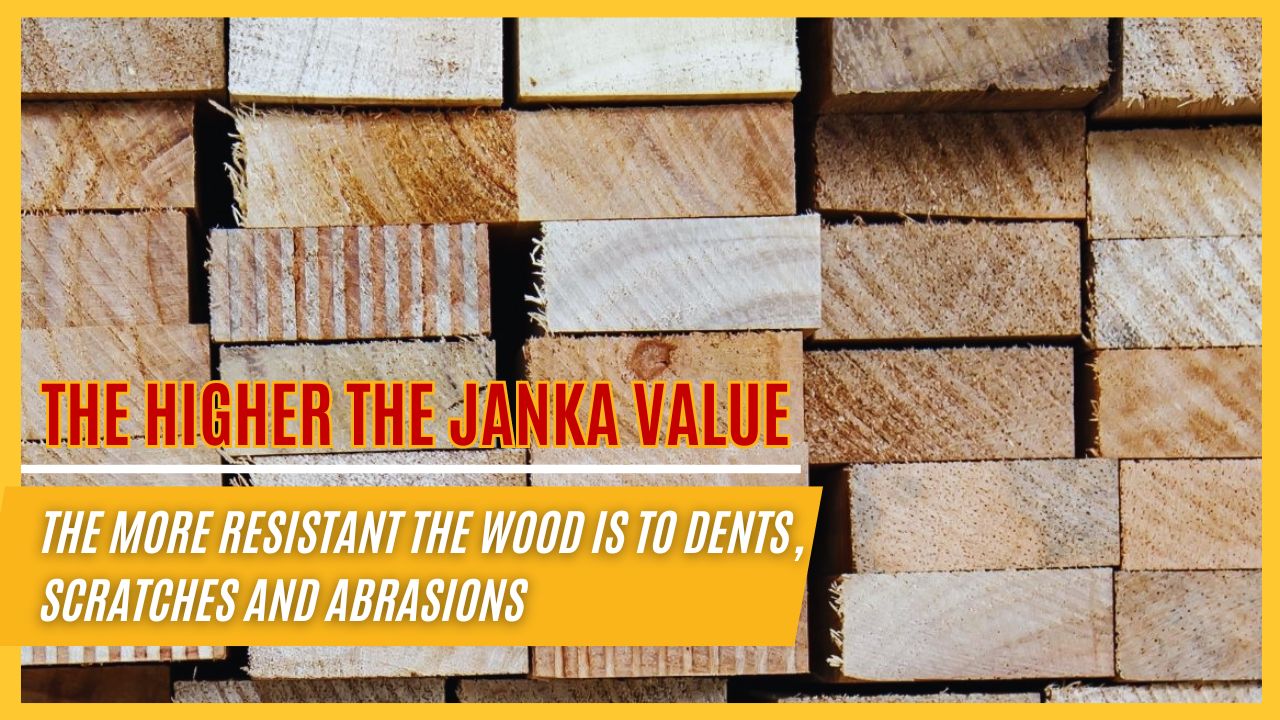

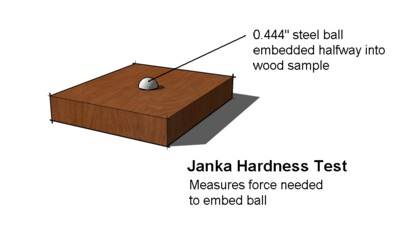

The Janka hardness test measures the force required to embed a steel ball of 11.28 millimeters (0.444 inches) in diameter halfway into the wood sample. The higher the Janka Wood hardness value, the more resistant the wood is to denting and wear.

The Significance of Janka Rating in the Wood Industry

The Janka Rating is a critical parameter in the wood industry that serves as the standard measure for wood hardness. It provides a unified system for evaluating the resistance and durability of different wood species. Here are some key points about its significance:

- Durability: The higher the Janka value, the more resistant the wood is to dents, scratches and abrasions. This is especially important for woods used in high-traffic areas such as floors, stairs, and countertops.

- Choosing the right wood: Janka Rating helps consumers and designers make informed choices about the right type of wood for a specific use. For example, red oak has a high Janka Rating (1290 lbf) making it suitable for floors, while pine (420 lbf) is softer and suitable for other interior projects.

- Compare wood types: Janka Rating provides a unified standard for comparing the hardness of different wood types, making it easier for consumers to make decisions.

The Janka Rating goes beyond simply measuring wood hardness. It also provides valuable insights into a wood’s resistance to indentation and its workability during various woodworking processes. This information can be crucial for users in making informed decisions about the right wood species for their projects.

The Janka Rating Measurement Method

The Janka measurement method is standardized by ASTM International (American Society for Testing and Materials) under the code ASTM D143. The specific measurement process is as follows:

Step 1: Wood Sample Preparation

The wood sample is cut into a square with a minimum size of 2 inches (5 cm) and a thickness of 1 inch (2.5 cm). The surface of the wood sample is sanded smooth and flat.

Step 2: Testing

- A steel ball with a diameter of 11.28 mm (0.444 inches) is placed on the surface of the wood sample.

- Force is applied to the steel ball through a piston until it is embedded halfway into the wood.

- This force is recorded in pound-force (lbf) or newton (N).

Step 3: Janka Rating Calculation

The Janka Rating is calculated by dividing the measured force by the contact area between the steel ball and the wood (100 mm²).

Formula:

Janka Rating = Force / Area (lbf/in² or N/mm²)

Example:

- If the force required to embed the steel ball halfway into the wood is 1000 lbf, then the Janka Rating of the wood is 10 lbf/in².

- If the force required to embed the steel ball halfway into the wood is 6895 N, then the Janka Rating of the wood is 68.95 N/mm².

Note:

- The Janka Rating is just one factor to consider when selecting wood. Other factors such as durability, aesthetics, cost, and availability should also be considered.

- There are several other methods for evaluating wood hardness, but the Janka Rating is the most common and widely used method.

Impact of Janka Rating on Wood Price and Quality

The popularity of the Janka Rating has made it an important factor affecting both the price and quality of wood.

Janka Rating plays a significant role in determining the quality of wood. A high Janka Rating value generally indicates that the wood is harder, more resistant to force, and less susceptible to damage from impact. For applications such as flooring, furniture, or construction materials, wood with a high Janka Rating is often preferred due to its ability to maintain its shape and surface appearance for a longer period.

The price of wood often directly reflects its Janka Rating value. Wood with a high Janka Rating is generally more expensive than wood with a low Janka Rating. This is because the process of grading and processing wood with a high Janka Rating typically requires more advanced technology and techniques, which increases the production cost. Conversely, wood with a low Janka Rating is often used in applications where high hardness is not a major requirement. For example, Mussivi wood (Janka Rating 1810) is more expensive than pine wood (Janka Rating 380).

However, it is important to note that the Janka Rating is not the only factor that determines the price and quality of wood. Other factors such as thickness, wood grain, color, and rarity also affect the value of wood.

Conclusion

The Janka Wood Hardness is a useful tool for understanding the hardness of wood and helping you make informed decisions when choosing the right type of wood for your intended purpose. By understanding the implications of different Janka values, you can weigh factors such as durability, cost, and aesthetics to select the wood that provides the best value for your needs.

![[K-Timber] Blog Post Boder](https://k-timbers.com/wp-content/uploads/2024/06/K-Timber-Blog-Post-Boder.jpg)