Padauk wood is a beautiful and exotic hardwood known for its distinctive reddish-brown color. It is a hardwood in the genus Pterocarpus, which includes many different species. However, the most popular type of padauk is African padauk. In general, different types of padauk have different properties, appearances, and uses. African padauk is known for its exceptional durability and excellent rot resistance, making it an ideal choice for many outdoor projects. So let’s learn more about this type of Padauk wood with K-TIMBER in the article below.

Table of Contents

(Takula) Padauk Wood General information

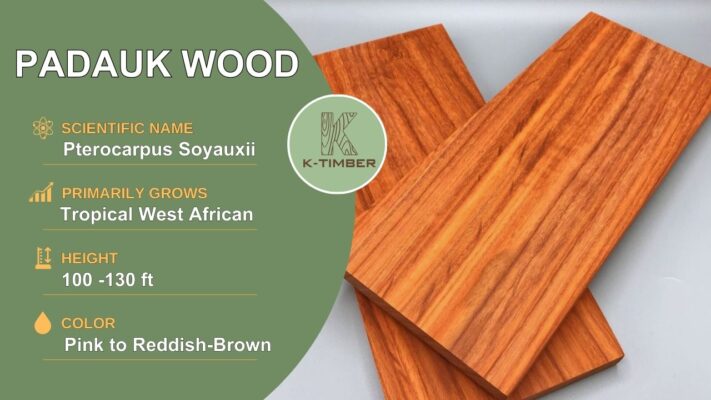

African padauk wood (Pterocarpus soyauxii), also known as vermilion, is a beautiful and exotic African hardwood that stands out from other hardwoods. It is found primarily in the evergreen or semi-deciduous forests of West Africa, Angola, Mozambique, Zambia, Zimbabwe, the Democratic Republic of the Congo, etc. Padauk trees can grow up to 100 feet tall and have a trunk diameter of up to 3 feet.

Padauk wood is a favorite choice of many woodworkers because it is easy to work with, has a unique appearance, and is less expensive than other hardwoods. It is used in a variety of applications, including heavy industries and furniture design. In some areas, padauk wood is often referred to by different names, such as takula, padauk, paduk, and padouk.

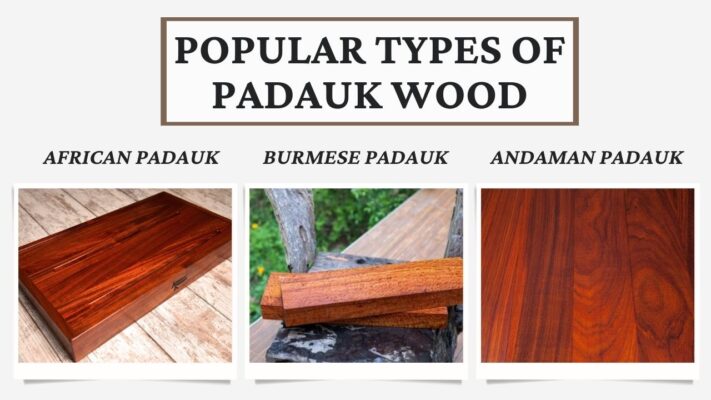

Popular types of Padauk wood

Padauk wood is a hardwood native to Asia or Africa that is known for its beautiful reddish-brown color, strength, and stability when working. These characteristics often lead it to be confused with other mahoganies, which also belong to the genus Pterocarpus. There are three main types of padauk wood:

- African padauk (Pterocarpus soyauxii): Native to West and Central Africa, it is known as vermilion for its bright, distinctive reddish-orange color. The heartwood can darken and lighten over time. With straight grain, open and coarse texture, this type of wood has a beautiful natural luster.

- Burmese padauk (Pterocarpus macrocarpus): Native to Myanmar and Thailand, Burmese padauk has heartwood that is yellow-red and gradually turns yellow-brown over time. However, with the interwoven grain structure, the workability also becomes more difficult.

- Andaman padauk (Pterocarpus dalbergioides): Found in the Andaman Islands (India). Similar to African and Burmese padauk, this type of wood has a darker color and turns to reddish-brown purple after cutting. Andaman padauk has excellent durability and resistance to rot and insects.

(Takula) Padauk Wood Properties

Color and Texture

Padauk wood is available in a variety of colors, from pale pink to deep reddish-brown. The color of the wood will vary depending on the species of tree and the growing conditions. Padauk wood also has very distinctive grain patterns, which can be straight, wavy, or interlocking. African padauk has a normal grain, while Andaman padauk has a rare interlocking grain. The wood texture is coarse and has a beautiful natural luster.

Padauk wood is often finished with a UV finish to prevent or delay the color change over time. However, padauk wood can also be kept in its natural appearance by using other finishing methods, such as polishing or varnishing.

Density and strength

Padauk wood is a strong, dense hardwood with an average dry weight of about 47 lbs/ft3 (745 kg/m3). This makes it an ideal choice for applications with high wear and tear, such as flooring, stairs, and furniture.

Padauk is also one of the hardest hardwoods available, with a hardness ranging from 1,710 lbf (7,580 N) to 1,970 lbf (8,760 N). This hardness gives the wood good resistance to physical impacts, such as impact and scratches.

In addition, padauk has natural rot and insect resistance, making it a good choice for outdoor applications, where wood is often exposed to the elements.

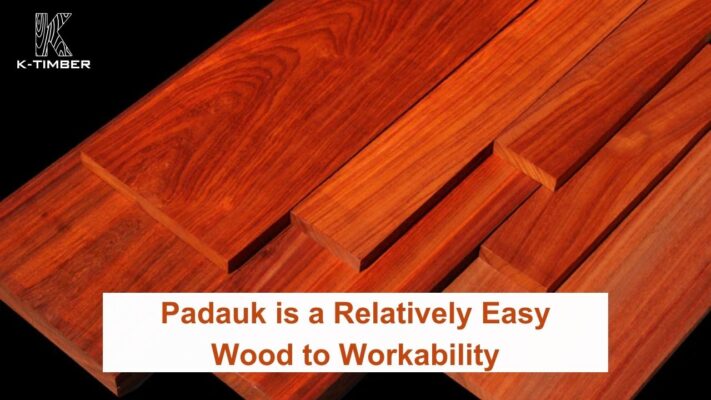

Workability

Padauk is a relatively easy wood to work with, although some precautions must be taken to avoid tear out, especially when planning quartersawn or interlocked grain. It turns and glues well, making it a versatile choice for various woodworking projects.

To achieve a smooth, glass-like surface, it’s usually necessary to fill the large open pores of padauk wood. Reactive oil-based finishes, such as polyurethane, may have curing issues if the heartwood is not sealed properly beforehand.

(Takula) Padauk Wood Technical Properties

| TECHNICAL PROPERTIES | VALUE |

| Average Dried Weight | 46.5 lbs/ft3 (745 kg/m3) |

| Specific Gravity (Basic, 12% MC) | 0.63, 0.75 |

| Janka Hardness | 1,710 lbf (7,580 N) – 1,970 lbf (8,760 N) |

| Modulus of Rupture | 18,380 lbf/in2 (126.7 MPa) |

| Elastic Modulus | 1,895,000 lbf/in2 (13.07 GPa) |

| Crushing Strength | 9,240 lbf/in2 (63.7 MPa) |

| Shrinkage | Radial: 3.1%

Tangential: 5.0%, Volumetric: 7.9% T/R Ratio: 1.6 |

(Takula) Padauk Wood Advantages

- Rich and distinctive color: Padauk wood is known for its vibrant red-orange color, which can deepen to a rich brown over time. This unique color makes it a highly sought-after wood for various applications.

- Exceptional durability: Padauk wood is exceptionally dense and strong, making it highly resistant to wear, tear, and impact. This durability makes it an excellent choice for high-traffic areas and applications that demand long-lasting performance.

- Natural resistance to pests and rot: Padauk wood is naturally rich in oils and resins, making it highly resistant to insect damage and fungal growth.

- Durability and Stability: Padauk wood is exceptionally durable and dimensionally stable, meaning it resists warping, shrinking, and swelling due to changes in humidity or moisture.

- Workability and Finishing: Padauk wood is relatively easy to work with, responding well to cutting, shaping, and carving using both hand and power tools.

(Takula) Padauk Wood Disadvantages

- Difficulty in finishing: Padauk wood has an open grain, making it challenging to achieve a smooth and flawless finish. The wood tends to absorb finishes unevenly, requiring careful preparation and multiple coats.

- Potential for allergic reactions: Padauk sawdust can trigger allergic reactions in some individuals, causing skin irritation, respiratory issues, or sensitization.

- Susceptibility to Fading: Padauk wood is prone to fading over time, especially when exposed to direct sunlight.

- Tool Wear and Tearout: Padauk wood’s high density and interlocked grain can sometimes cause blunting of cutting tools or result in tear out when planning.

- Limited Availability: Padauk wood is not as readily available in all parts of the world. This can make it challenging to source and may result in higher costs for transportation and acquisition.

5 potential risks when importing wood from Africa

Padauk wood is a valuable hardwood that is prized for its beauty and durability. However, importing padauk wood from Africa can be a risky proposition for many wood importers. Here are some of the potential risks that importers need to be aware of:

- Unstable prices: Padauk wood prices can fluctuate wildly due to a variety of factors, such as supply and demand, political instability, and currency fluctuations. This makes it difficult for importers to predict and plan their purchases.

- Declining production: Padauk wood production is declining due to deforestation, forest fires, and drought. This is making padauk wood supplies increasingly scarce and driving up prices.

- Unquality wood: Not all padauk wood suppliers provide quality wood. The quality of wood depends on a number of factors, such as the growing process, harvesting, and processing. The limited communication between importers and suppliers, which is often limited to images and videos, makes it difficult to control the quality of wood.

- Scam: There are countless African wood suppliers on the market who are willing to provide low-quality or fake wood, or even simply take the money and disappear, causing serious economic losses to importers.

- Delayed transportation: The long distance between Africa and other countries makes transportation of wood prone to delays. This can affect the production and business progress of importers and miss the “golden time” in business.

So what is the solution for wood traders to avoid the potential risks above?

Importing Angolan wood can be a potential business opportunity, but it also poses many risks. Importers need to do their research on the wood market, including prices, supply, and quality, and especially, choose a reputable supplier. K-TIMBER is proud to be a leading supplier of high-quality, reliable Angolan wood in the world.

- With over 20 years of experience in the African timber export industry, we provide our customers with FAS-grade timber products at a price that is 20% lower than the market.

- At K-TIMBER, we are committed to sourcing and exporting African timber from sustainable tropical forests. We work with the people of Angola to implement forest protection measures, including replanting forests after harvesting, using environmentally friendly logging methods, and Supporting local communities in forest management

- K-TIMBER’s strong relationship with the Angolan government makes it easy to export timber from K-TIMBER and ensures that our products are of the highest quality when they reach our customers.

- We closely monitor and handle all issues related to import and export procedures, timber harvesting, and timber processing to provide our customers with the best shopping experience.

- K-TIMBER has a team of professional staff with many years of experience in the import and export industry, always ensuring that the timber transportation process is smooth and fast, with a maximum transportation time of 60 days.

Contact K-TIMBER today for a consultation and the best price!