Common wood defects can be caused by natural factors or during the seasoning process. These defects can reduce the quality of wood, and reduce the aesthetic value and durability of wood products. Wood is a precious raw material, but it is also very vulnerable to damage. Wood defects can occur from the seedling stage to the final stages of seasoning. These defects can seriously affect the quality and durability of wood, making it more difficult to use.

Therefore, it is essential to identify and know how to handle wood defects. In the following article, K-TIMBER will answer the causes and solutions of the TOP 11 common wood defects.

Table of Contents

Types of wood defects: Natural

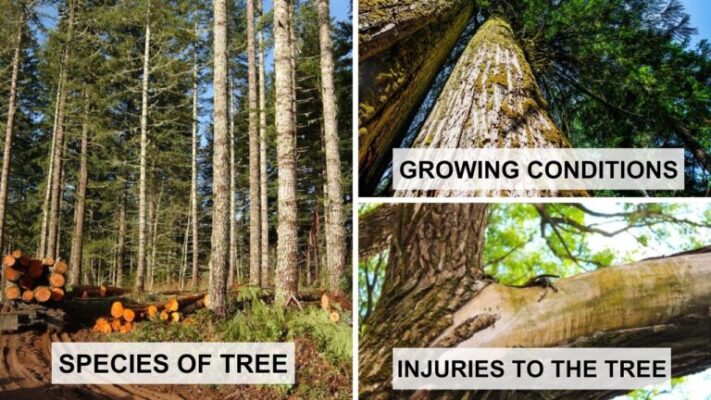

During its growth, a tree is exposed to many natural factors that can cause defects in the wood. Wormholes, knots, cracks, and rot are some of the most common wood defects that carpenters often encounter.

Wind cracks

Wind cracks are small, shallow cracks that appear on the surface of wood that is exposed to strong winds. These cracks are caused by the wood drying too quickly, which causes the surface to shrink and crack. Wind cracks are not usually major structural defects, but they can make the wood more susceptible to rot. Wind cracks typically appear as long, narrow cracks on the surface of the wood.

Some types of hardwoods, such as oak and maple, are more susceptible to wind cracks than softwoods, such as pine and cedar. Wood that is too dry is also a common cause of wind cracks.

To prevent this defect, the best way to prevent wind cracks is to take steps to prevent the wood from drying too quickly. This includes applying a finish to the wood surface, conditioning the wood regularly, and storing the wood properly. Shallow cracks can be filled with wood putty or a similar material. Deeper cracks may need to be repaired with epoxy resin or a similar adhesive.

Knots

Knots are one of the most common defects in wood caused by the presence of a branch. When a branch dies, it leaves a scar on the trunk of the tree. This scar is eventually covered over by new growth, but the grain of the wood is interrupted around the scar. This interruption is what causes a knot. Knots can be found in all types of wood, but they are more common in hardwoods.

In European countries, knot defects in wood are considered to be part of the natural beauty of wood. They can create unique and striking features, making wooden products more eye-catching and sophisticated. Many European consumers are willing to pay a premium for wooden products with beautiful knots.

In contrast, in Asian countries, such as Vietnam and China, knot defects in wood are often considered to be a flaw that reduces the value of the wood. Wooden products with knots are often graded lower and have lower prices.

To reduce the appearance of knots in wood, woodworkers will often use several remedies, such as sanding the surface of the wood smooth and filling the knots with wood putty or epoxy resin.

In some cases, it may be necessary to remove the knots from the wood. This can be done by drilling out the knot and filling the hole with wood putty or epoxy resin. However, removing knots can weaken the wood, so it is important to only remove loose or problematic knots.

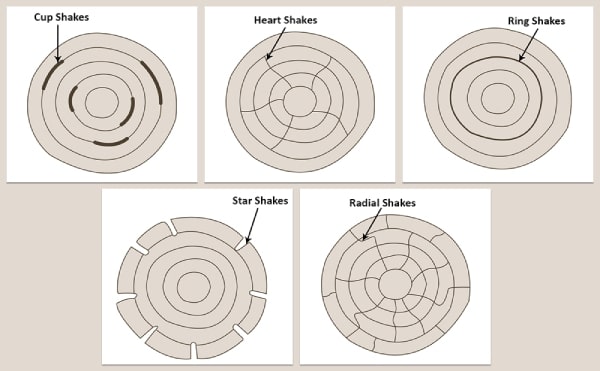

Shakes

Shakes are another type of crack that causes the wood fibers to separate between annual growth rings, often extending across the entire face of the board. They can occur in either the heartwood or sapwood.

The exact cause of shakes is not fully understood, but they are thought to be caused by a combination of factors, including stress, fungi, or the bacteria Pseudomonas Fluorescens.

There is no cure for shakes, but there are a few things that can be done to prevent them or to reduce their severity:

- Proper tree care: Trees should be kept healthy and vigorous to reduce stress.

- Seasoning: Wood should be properly seasoned to reduce moisture content and prevent further cracking.

- Avoid using shakes in critical applications: Shakes should not be used in applications where strength or appearance is important.

Ring galls

Ring galls are abnormal growths that occur on the surface of trees. They are caused by the tree’s reaction to an injury, such as a branch being broken off. The tree produces a callus to protect the wound, but this can sometimes cause a bulge to form. Ring galls can also be caused by insects or diseases.

The most common cause of rind galls is improper pruning. When a branch is cut too close to the trunk, the tree may try to heal the wound by overgrowing the area. Other causes of rind galls include insects, diseases, and mechanical damage.

Rind galls can be prevented by pruning branches correctly. When pruning a branch, make sure to cut it at least 1 inch (2.5 cm) away from the trunk. You should also use sharp tools, and avoid making jagged cuts.

If a rind gall does form, it can be removed by cutting it off with a sharp knife. However, it is important to note that this will leave a scar on the tree. In some cases, it may be necessary to remove the entire tree if the rind galls are severe.

Coarse grain

Coarse grain is a defect in wood caused by large, uneven growth rings. These rings are typically found in trees that have grown rapidly, such as those that have been grown in plantations. Coarse grain is most common in softwoods, such as pine and spruce.

There are several factors that can contribute to coarse grain defects in wood, including:

There is no way to eliminate coarse grain in wood, but there are a few things that can be done to minimize its impact. Some species of natural wood tend to have coarser grain than others.

If you are looking for wood with a fine grain, consider using species such as Iroko, maple, Sapele, or Musivi. All of these high-quality woods are available from K-TIMBER, the world’s leading supplier of African timber.

In addition, the way wood is dried can also affect the appearance of the grain. Proper drying can help prevent warping and cracking. Lumber should be dried slowly and evenly to ensure uniform moisture content throughout the wood.

Insects

Wood-boring insects are a common problem for buildings and wooden structures. Beetles, moths, termites, and wasps are all “silent invaders.” These defects can range from minor aesthetic flaws to serious structural damage. Wood-boring insects produce sawdust-like “frass”. Their holes are usually round and randomly scattered on the surface of the wood.

- Termites: These are social insects that live in colonies, divided into many castes. Termites eat wood from the inside, creating tunnels and holes. Over time, the wood will rot and break apart.

- Beetles: Beetles destroy sapwood. The small holes created by beetles can disrupt the internal structure of the wood.

- Marine borers: They are often found near coastal areas. Marine borers create large holes in wood, making the wood weak and discolored.

To prevent and control wood defects caused by insects, users should use processed wood that has been treated with chemicals, store wood in a dry and cool place, and check the wood regularly for signs of insect damage.

Dry rot

Dry rot, also known as Serpula lacrymans, is a type of fungus that attacks timber. It is a serious problem because it can cause significant structural damage to buildings. Dry rot fungi thrive in damp, poorly ventilated conditions. They feed on the cellulose in wood, which weakens the wood and makes it more susceptible to collapse.

Treatment of dry rot typically involves removing the affected wood and any surrounding masonry that is also affected. The area is then treated with a fungicide to kill any remaining spores.

In some cases, dry rot can be treated in place without removing the affected wood. However, this can only be done if the condition is detected early and the treatment is done correctly.

Prevention is always better than cure, so it is important to take steps to reduce the risk of dry rot such as regularly checking moisture levels, using high-quality wood, and promptly treating damaged wood.

Types of wood defects: Seasoning

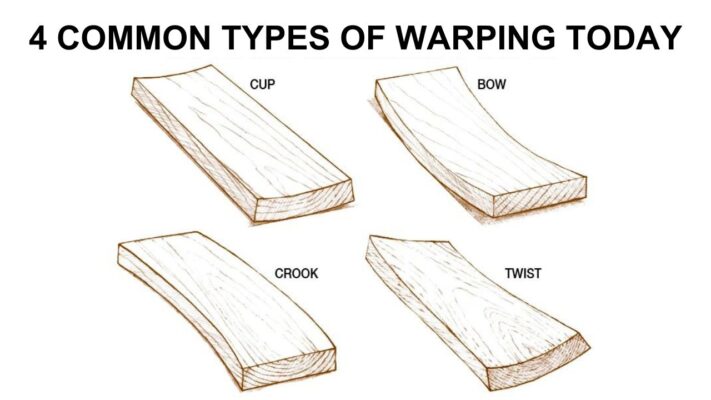

Warping

Warping is a common wood defect that occurs when wood absorbs or loses moisture unevenly, causing it to deviate from its flat or straight form. Warping can affect the structural integrity of wood and make it difficult to use for construction or woodworking projects.

The main cause of warping in wood is due to storage conditions. These causes can include uneven finishing, changes in moisture content, seasoning, exposure to ultraviolet (UV) light, and high temperatures combined with wood cut to too thin a size. Warping mainly occurs due to uneven expansion or contraction caused by abnormal changes in moisture.

Once the wood has warped, it is very difficult to restore it to its original shape. However, there are several things that can be done to minimize the appearance of warping or prevent warping from occurring further, such as storing wood in a dry, well-ventilated place. In some cases, it may be necessary to plane the wood to remove the warped areas.

Checks and Splits

Checks and splits are two common wood defects that occur when the fibers of the wood separate. Checks are typically shallow cracks that run along the length of the board, while splits are deeper cracks that can extend through the board. Both checks and splits can weaken the wood and make it more susceptible to rot and decay.

There are several causes of cracks and chips in wood. The most common cause is rapid drying. When wood dries too quickly, the moisture in the outer layers of the wood evaporates, causing the outer layers to shrink.

Small checks and splits can sometimes be repaired with wood putty or epoxy. However, larger checks and splits may need to be replaced with a new piece of wood.

Once the wood has been dried and processed, checks and splits can be prevented by using appropriate finishing materials. For example, polyurethane sealants can help to fill in cracks and prevent water from penetrating the wood.

Case harden

Case hardening is a wood defect that occurs when lumber dries too quickly. This can cause the outer layers of the wood to dry out and shrink before the inner layers can, resulting in internal stresses that can lead to a variety of problems.

To prevent or correct case hardening, K-TIMBER recommends that you dry wood at a moderate rate. Avoid using high drying temperatures. The ideal drying temperature is about 120-150°F (49-65°C). Maintain the humidity in the drying chamber at around 60-70%.

Learn more: (Takula) Padauk Wood: Properties, Characteristics & Uses

Collapse

Collapse is a type of wood defect that occurs when the wood cells shrink and collapse unevenly during the drying process. This can cause the wood to distort and become wavy or rippled. Collapse is most commonly seen in timber that has been dried too rapidly, particularly in the early stages of the drying process.

The best way to prevent collapse is to dry the wood at a controlled rate and to ensure that all parts of the wood dry evenly. In some cases, collapsed wood can be covered with a surface treatment, such as paint or varnish, to conceal the defect.

Where to import quality African Wood?

Looking for a reliable and high-quality source of African timber? K-TIMBER offers a wide variety of high-quality Angolan timber from sustainable tropical forests. We guarantee a clear source of wood, with a rigorous extraction and processing process to ensure the best products for our customers.

![[K-Timber] Blog Post Boder (1)](https://k-timbers.com/wp-content/uploads/2024/06/K-Timber-Blog-Post-Boder-1.jpg)